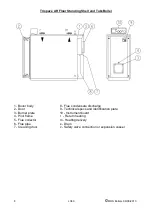

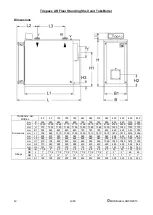

Trispace AR Floor Standing Shell and TubeBoiler

16 L360

©

MHS Boilers 06/09/2013

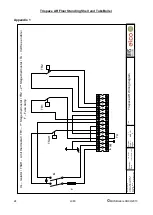

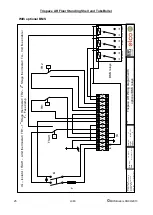

23 BURNER CONNECTION

For installation of the burner, the electrical connections and the necessary settings, consult the burner

instruction manual.

Ascertain that the correct type of burner has been chosen for the boiler, checking the technical specifications

of both.

The burner draught tube must be sized as shown below:

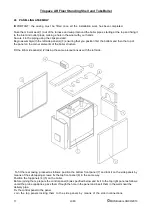

Secure the burner to the door by means of the fixing plate so that the flame is parallel and centred in

the furnace; if not, combustion problems can occur with the risk of seriously damaging the boiler.

IMPORTANT: after installing the burner, fill any space between the draught tube and the hole of the door

with the material provided, resistant to 1000°C (ceramic fibre mat).

This operation prevents overheating of the door which would otherwise be permanently deformed.

For models TRISPACE AR from 135 to 800: If the burner is provided with an air intake, connect it by means of

a rubber tube to the intake located on the flame inspection window: in this way the glass will remain clear.

If the burner is not provided with air intake, remove the intake on the flame inspection window and close the

hole with a

∅

1/8” BSP plug.

The fuel connections to the burner must be positioned in order to permit complete opening of the boiler door

with the burner fitted

CERAMIC FIBRE