ELCO S.r.l. - ELK 38 - OPERATING INSTRUCTIONS - Vr. 02 - ISTR 06261 - PAG. 4

Connect the instrument as far away as possible from sources of

electromagnetic disturbances such as motors, power relays, relays,

solenoid valves, etc.

3.3 - ELECTRICAL CONNECTION

Carry out the electrical wiring by connecting only one wire to each

terminal, according to the following diagram, checking that the

power supply is the same as that indicated on the instrument and

that the load current absorption is no higher than the maximum

electricity current permitted.

As the instrument is built-in equipment with permanent connection

inside housing, it is not equipped with either switches or internal

devices to protect against overload of current: the installation will

include a two-phase circuit-breaker, placed as near as possible to

the instrument, and located in a position that can easily be reached

by the user and marked as instrument disconnecting device which

interrupts the power supply to the equipment.

It is also recommended that all the electrical circuits connected to

the instrument must be protect properly, using devices (ex. fuses)

proportionate to the circulating currents.

It is strongly recommended that cables with proper insulation,

according to the working voltages and temperatures, be used.

Furthermore, the input cable of the probe has to be kept separate

from line voltage wiring. If the input cable of the probe is screened, it

has to be connected to the ground with only one side.

Whether the instrument is 12 V version it’s recommended to use an

external transformer TCTR, or with equivalent features, and to use

only one transformer for each instrument because there is no

insulation between supply and input.

We recommend that a check should be made that the parameters

are those desired and that the application functions correctly before

connecting the outputs to the actuators so as to avoid

malfunctioning that may cause irregularities in the plant that could

cause damage to people, things or animals.

ELCO S.r.l. and its legal representatives do not assume any

responsibility for any damage to people, things or animals

deriving from violation, wrong or improper use or in any case

not in compliance with the instrument’s features.

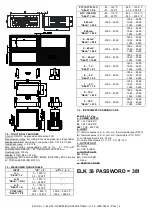

3.4 - ELECTRICAL WIRING DIAGRAM

4 - FUNCTIONS

4.1 - MEASURING AND VISUALIZATION

All the parameters referring measurements are contained in the

group “

]

InP”.

Depending on the model required the input accept:

C: Thermocouples temperature probes (J,K,S and ELCO IRS

Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermoresistances PT100.

E : Thermocouples temperature probes (J,K,S and ELCO IRS

Infrared sensors), mV signals (0..50/60 mV, 12..60 mV),

Thermistors PTC and NTC.

I : normalized analogue signals 0/4..20 mA

V : normalized analogue signals 0..1 V, 0/1..5 V, 0/2..10 V

Depending on the model, using par. “SEnS”, it’s possible to select

the type of input probe, which can be :

- for thermocouples J (J), K (CrAL), S (S) or for infrared sensors

serie ELCO IRTC1 with linearization J (Ir.J) or K (Ir.CA)

- for thermoresistances Pt100 IEC (Pt1) or thermistors PTC KTY81-

121 (Ptc) or NTC 103AT-2 (ntc)

- for normalised signals in current 0..20 mA (0.20) or 4..20 mA

(4.20)

- for normalised signals in tension 0..1 V (0.1), 0..5 V (0.5), 1..5 V

(1.5), 0..10 V (0.10) or 2..10 V (2.10).

- for normalised signals in tension 0..50 mV (0.50), 0..60 mV (0.60),

12..60 mV (12.60).

We recommend to switch on and off the instrument when these

parameters are modified, in order to obtain a correct measuring.

For the instruments with input for temperature probes (tc, rtd) it’s

possible to select, through par. “Unit”, the unit of measurement

(°C, °F) and, through par. “dP” (Pt100, PTC and NTC only) the

desired resolution (0=1°; 1=0,1°).

Instead, with regards to the instruments with normalised analogue

input signals, it is first necessary to program the desired resolution

on par. “dP” (0=1; 1=0,1; 2=0,01; 3=0,001) and then, on par.

"SSC", the value that the instrument must visualise at the beginning

of the scale (0/4 mA, 0/12 mV, 0/1 V o 0/2 V) and, on par. "FSC",

the value that the instrument must visualise at the end of the scale

(20 mA, 50 mV, 60 mV, 5 V or 10 V).

The instrument allows for measuring calibration, which may be used

to recalibrate the instrument according to application needs, by

using par. “OFSt” and “rot”.

Programming par. “rot”=1,000, in par. “OFSt” it is possible to set a

positive or negative offset that is simply added to the value read by

the probe before visualisation, which remains constant for all the

measurements.

If instead, it is desired that the offset set should not be constant for

all the measurements, it is possible to operate the calibration on

any two points.

In this case, in order to decide which values to program on par.

“OFSt” and “rot”, the following formulae must be applied :

“rot” = (D2-D1) / (M2-M1)

“OFSt” = D2 - (“rot” x M2)

where:

M1 =measured value 1

D1 = visualisation value when the instrument measures M1

M2 =measured value 2

D2 = visualisation value when the instrument measures M2

It then follows that the instrument will visualise :

DV = MV x “rot” + “OFSt”

where: DV = visualised value

MV= measured value

Example 1: It is desired that the instrument visualises the value

effectively measured at 20° but that, at 200°, it v isualises a value

lower than 10° (190°).

Therefore : M1=20 ; D1=20 ; M2=200 ; D2=190

“rot” = (190 - 20) / (200 - 20) = 0,944

“OFSt” = 190 - (0,944 x 200) = 1,2

Example 2: It is desired that the instrument visualises 10° whilst the

value actually measured is 0°, but, at 500° it visu alises a 50° higher

value (550°).

Therefore : M1=0 ; D1=10 ; M2=500 ; D2=550

“rot” = (550 - 10) / (500 - 0) = 1,08

“OFSt” = 550 - (1,08 x 500) = 10

By using par. “FiL” it is possible to program time constant of the

software filter for the input value measured, in order to reduce noise

sensitivity (increasing the time of reading).

In case of measurement error, the instrument supplies the power as

programmed on par. “OPE”.

This power will be calculated according to cycle time programmed

for the PID controller, while for the ON/OFF controllers the cycle

time is automatically considered to be equal to 20 sec. (e.g. In the

event of probe error with ON/OFF control and “OPE”=50, the control

output will be activated for 10 sec., then it will be deactivated for 10

sec. and so on until the measurement error remains.).

ELK