63

•

you use rigid pipes or a flexible pipe complying with applicable local regulations. The fle-

xible pipe shall be of the correct construction for the type of gas being used.

•

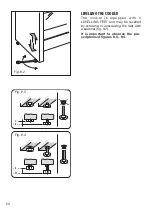

if compression fittings are used, you tighten them firmly using two spanners (fig. 10.6).

•

the connection with rigid metal pipes does not cause stress or pressure to the gas piping.

•

the flexible pipe is not under tension, twisted, kinked or too tightly bent, neither while the

appliance is in use nor while it is being connected or disconnected.

•

the flexiple pipe does not exceed 2000 mm in length (or refer to applicable local regula-

tions) and does not come into contact with sharp edges, corners or moving parts. Use a

single flexible pipe only; never connect the cooker with more than one flexible pipe.

•

the flexible pipe can easily be inspected along its entire length to check its condition; if it

has an expiry date, it should be replaced before that date.

•

if using a flexible pipe which is not entirely made of metal, make sure that it does not come

into contact with any part of the cooker with a surface temperature of 70°C or above (or

refer to applicable local regulations).

•

the hose is not subject to excessive heat by direct exposure to flue products or by contact

with hot surfaces.

•

the rigid or flexible pipe is replaced if it shows signs of wear or damage.

•

a gas pressure regulator, in compliance with the applicable local regulations, is installed

when connecting to an LPG cylinder.

•

you inform the customer that the cylinder valve or the supply valve immediately by the

appliance should be closed when the cooker is not in use.

•

you inform the customer that the rigid or flexible pipe should not be subjected to corrosion

by acidic cleaning agents.

After connecting the cooker to the gas supply, make sure that you

•

check that the connections are correctly sealed using a soapy solution, but never a naked

flame.

•

check whether the injectors are correct for the type of gas being used.

•

replace the sealing washer on the slightest sign of deformation or imperfection. The sea-

ling washer is the part which guarantees a good seal in the gas connection.

•

use two spanners when connecting the rigid or flexible pipe (fig. 10.6).

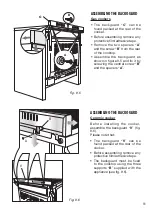

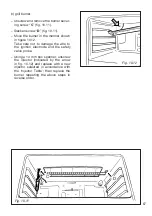

Gas connection with rigid or flexible pipe

Note: if already fitted on the inlet pipe, remove the rubber hose holder

Manifold

male

pipe fitting

Inlet pipe

1/2” G cylindrical

(ISO 228-1) female

Sealing

washer (#)

Rigid pipe

(not supplied)

Fig. 10.6

(#) If not already fitted on the inlet pipe,

it is supplied with the appliance in a

separate kit

1/2” G cylindrical

(ISO 228-1) female

Flexible pipe

(not supplied)