ROTATION FROM CENTER

0

240

-240

R

ES

IS

TA

N

C

E

FO

R

C

E

0

M

A

X

MINIMUM PRELOAD

ROTATION FROM CENTER

0

240

-240

R

ES

IS

TA

N

C

E

FO

R

C

E

0

M

A

X

MAXIMUM PRELOAD

OUTER

MIDDLE

INNER

140 lb.

173 lb.

197 lb.

197 lb.

24 lb.

57 lb.

116 lb.

2.0 TURNS MAX PRELOAD

2.0 TURNS MAX PRELOAD

2.5 TURNS MAX PRELOAD

57 lb.

81 lb.

116 lb.

2.5 TURNS MAX PRELOAD

3.0 TURNS MAX PRELOAD

3.5 TURNS MAX PRELOAD

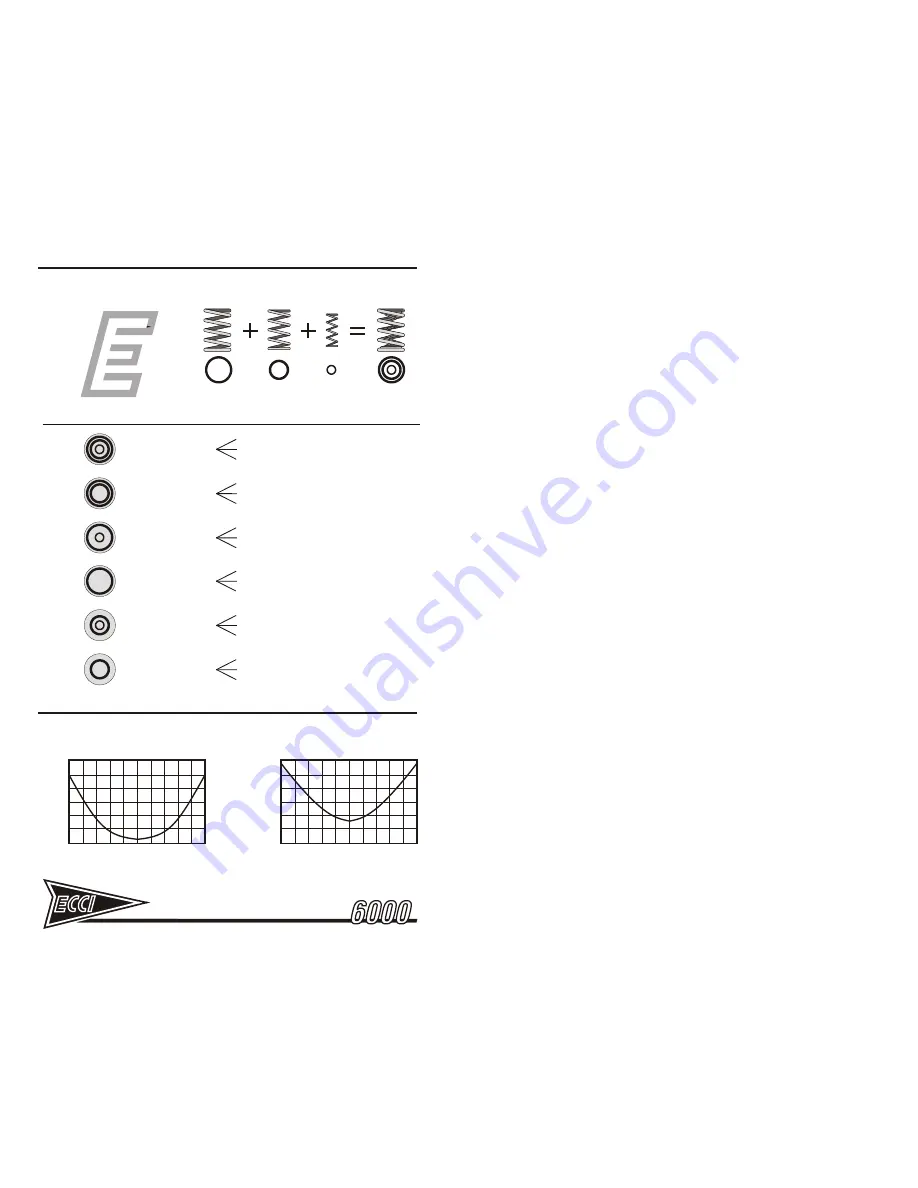

MONOPOINT II

CONCENTRIC

SPRING SYSTEM

2.0 TURNS FOR STRONGEST CENTERING FORCE

0.75 TO 1.25 TURNS FOR BALANCED FEEL

0.5 TURNS FOR LIGHTEST CENTERING

2.0 TURNS FOR STRONGEST CENTERING FORCE

0.75 TO 1.25 TURNS FOR BALANCED FEEL

0.5 TURNS FOR LIGHTEST CENTERING

2.5 TURNS FOR STRONGEST CENTERING FORCE

1 TO 1.5 TURNS FOR BALANCED FEEL

0.5 TURNS FOR LIGHTEST CENTERING

2.5 TURNS FOR STRONGEST CENTERING FORCE

1 TO 1.5 TURNS FOR BALANCED FEEL

0.5 TURNS FOR LIGHTEST CENTERING

3.5 TURNS FOR STRONGEST CENTERING FORCE

2.0 TO 2.5 TURNS FOR BALANCED FEEL

0.75 TURNS FOR LIGHT CENTERING

SPRING COMBINATIONS

PRELOAD RANGE AVAILABLE

3.0 TURNS FOR STRONGEST CENTERING FORCE

1.5 TO 2 TURNS FOR BALANCED FEEL

0.75 TURNS FOR LIGHT CENTERING

BALANCED RANGE IS RECOMMENDED FOR THE BEST COMBINATION OF SMOOTHNESS AND CENTER FEEL

COMBINATION

TRACKSTAR

Figure 24 - STEERING RESISTANCE SPRING COMBINATIONS

Figure 25 - STEERING CENTERING TUNING

1

WARNING! Do not exceed the maximum number of turns listed in the table

for the combination of springs being used – excessive pressure will damage

the steering camshaft. Exceeding the recommended number of turns is

considered MISUSE and damage from misuse is NOT covered under

warranty! Be careful!

2

Tighten the preload adjuster locknut, while holding the preload adjuster

screw in position with the hex key wrench.

Note: If the springs the springs make noise after installation, examine the

assembly to make certain that all springs are seated properly in their respective

pockets, both in the upper and lower spring retainer. Most noise issues are

caused by the large outer spring not being rotated against the spring stop screw

[Figure 22].

3.6

FLDS - FLUID DAMPED STEERING

The FLDS system uses a belt driven rotary fluid damper [Figures 6 & 26]. For

each wheel rotation the damper will rotate multiple times. The damping ratio

provided standard with the Trackstar 6000 provides a balance of damping and

spring resistance. Some users may wish to reduce or increase the amount of

damping. ECCI offers pulleys in several different ratios for purchase [Figure 27].

Generally, someone who uses many rapid wheel movement corrections while

driving may prefer a lighter pulley, while someone using very steady measured

wheel movements may prefer even heavier damping.

Steering wheel diameter also has an effect on damping force. Diameters smaller

than the standard 13-1/2 inch wheel will create less leverage on the steering

shaft. This will increase the level of damping perceived by the driver.

3.7

SHIFT PADDLE ADJUSTMENT

The Trackstar 6000 unit is provided with F-1 style behind-the-wheel paddles to

perform gear shift function. The paddles have a very short throw to make rapid

shifting possible. However, there is a small range of adjustment. The factory

setting provides a moderate amount of tolerance for the switch actuation point. If

throw adjustment needs to be reset, the stop screws can be adjusted with a hex

key and 3/8 in. wrench. If any button or paddle control remains on constantly or

does not trigger except at the very end of travel, adjustment will be needed.

Sometimes the switches will ‘wear in’ to a different engagement point than when

new and require readjustment after a period of time.

Depending on which steering wheel you have, stops may be located at the back

and in some cases the front of each paddle. Before making adjustments, make

sure the wheel and paddles are bolted tight to the steering hub. Unless

compressed in place by the steering wheel, paddle components may warp

slightly affecting the accuracy of the adjustment.

Before adjusting, loosen the locknuts of the stop screws with a 3/8” wrench. Find

the control trigger point with a continuity tester or by leaving the unit plugged in to

your computer and set to a calibration utility. When the trigger point is found, turn

the stop screws in gradually to ‘bracket’ this point to the desired tolerance. Be

careful to not adjust travel too close to the actuation point, for inconsistent

shifting operation may result. When finished make sure to tighten the locknuts to

ensure that the stop screws are securely locked in place.