XRGI

®

- INSTALLATION GUIDE

VERSION 1.0 2018

52

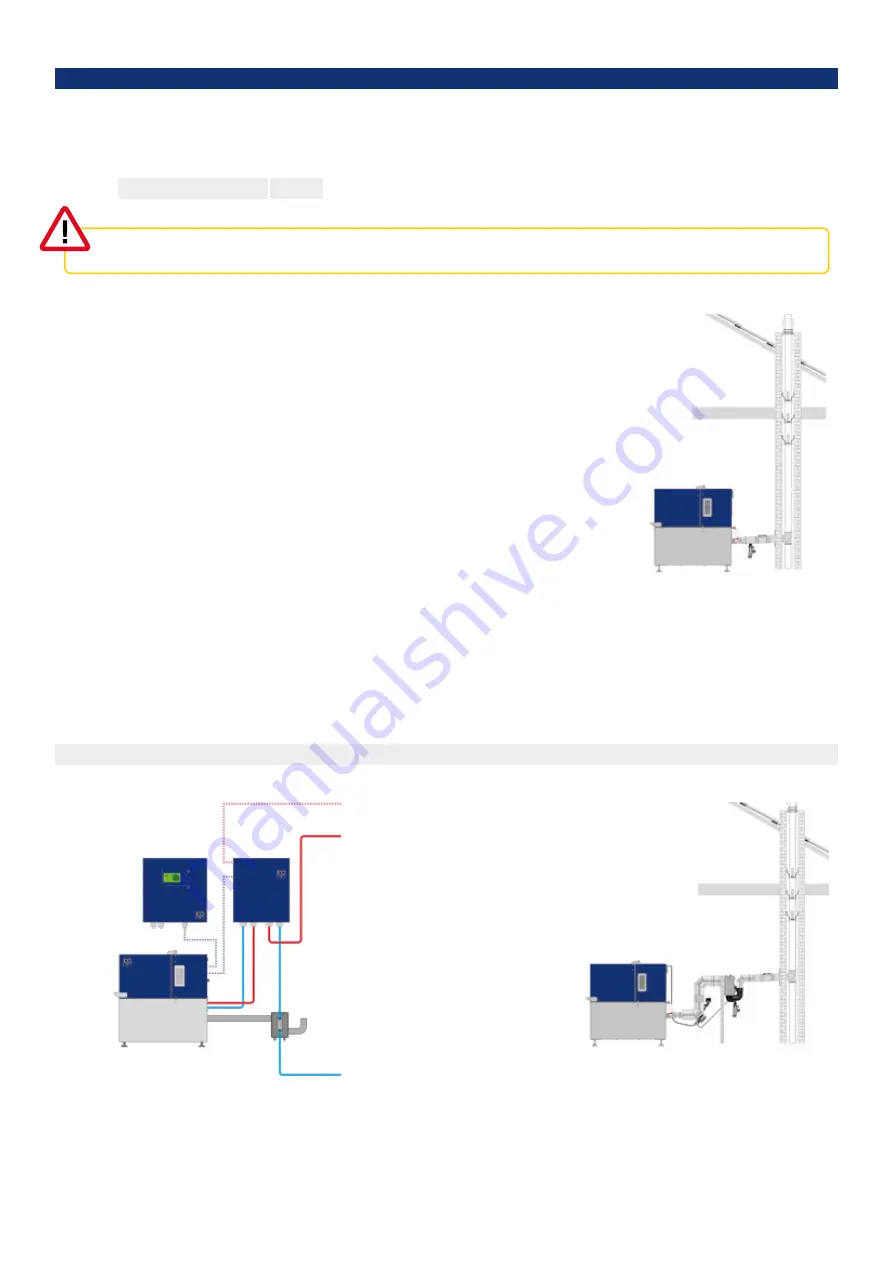

C O N D E N S I N G E X H A U S T

G A S H E AT E X C H A N G E R

to the Storage Tank

from the Storage Tank

5.2

E X H A U S T G A S S I D E I N S TA L L AT I O N

5.2.1 E X T E R N A L E X H A U S T H E AT E X C H A N G E R

E x h a u s t g a s c o n n e c t i o n o n t h e P o w e r U n i t

X R G I ® 6 / 9 / 1 5 / 2 0

DN 60

Discharge the exhaust gases from the Power Unit through an exhaust gas pipe. Install the exhaust gas system in accordance with

regulations applicable in the country of installation.

Make sure that the fresh air intake and the exhaust gas pipes comply with installation

type B (room air dependent). Only permit a qualified fitter to connect up the system.

The installation regulations of the exhaust system manufacturer are to be observed.

The Power Unit is not designed for condensing operation, nevertheless install a conden-

sate drain to trap and discharge any condensation produced when the system starts

up. Fit a condensate box with a large water reserve or a trap with a ball valve or similar

to prevent the condensate drain from drying out. Use exhaust gas lines that comply

with temperature class T160 or higher, since the exhaust gas temperatures involved are

continuously close to the permissible limit and the XRGI® system mainly runs for long

periods of time.

Make sure that the exhaust gas system is pressure-tight (pressure-resistant to 5,000 Pa,

type H1 or H2). Do not route condensate and exhaust gas pipes horizontally. Ensure that

they have a minimal gradient of 5% to allow the condensate to run off. Make sure that

the length of the exhaust gas line, with an internal diameter of 80 mm and up to five

bends, does not exceed 20 metres. Extrapolate in line with EN 13384 as required if there

are more than five bends or if the pipe is longer.

In principle, each XRGI® system needs a separate exhaust gas pipe. Exhaust gas pipes can be cascaded from the Power Unit side, but

the exhaust pipe must be approved for this purpose by the manufacturer. You may have to extrapolate the pressure conditions in line

with EN 13384.

You can add an external exhaust heat exchanger to the Power Unit to improve its thermal efficiency. However, a notable increase

in output can only be achieved in condensing operation. The return temperatures from the heating system should permanently lie

below 45 to 50 °C. After the external exhaust heat exchanger, flue pipes with approval 120 ° C (PP) are permitted.

Ensure that the exhaust gas pipe is gas-tight. Comply with all national fire regulations!

Fig. 5.18 – Assembly example

Fig. 5.16 – Assembly example

Fig. 5.17