Publication No.: 2753-20

4

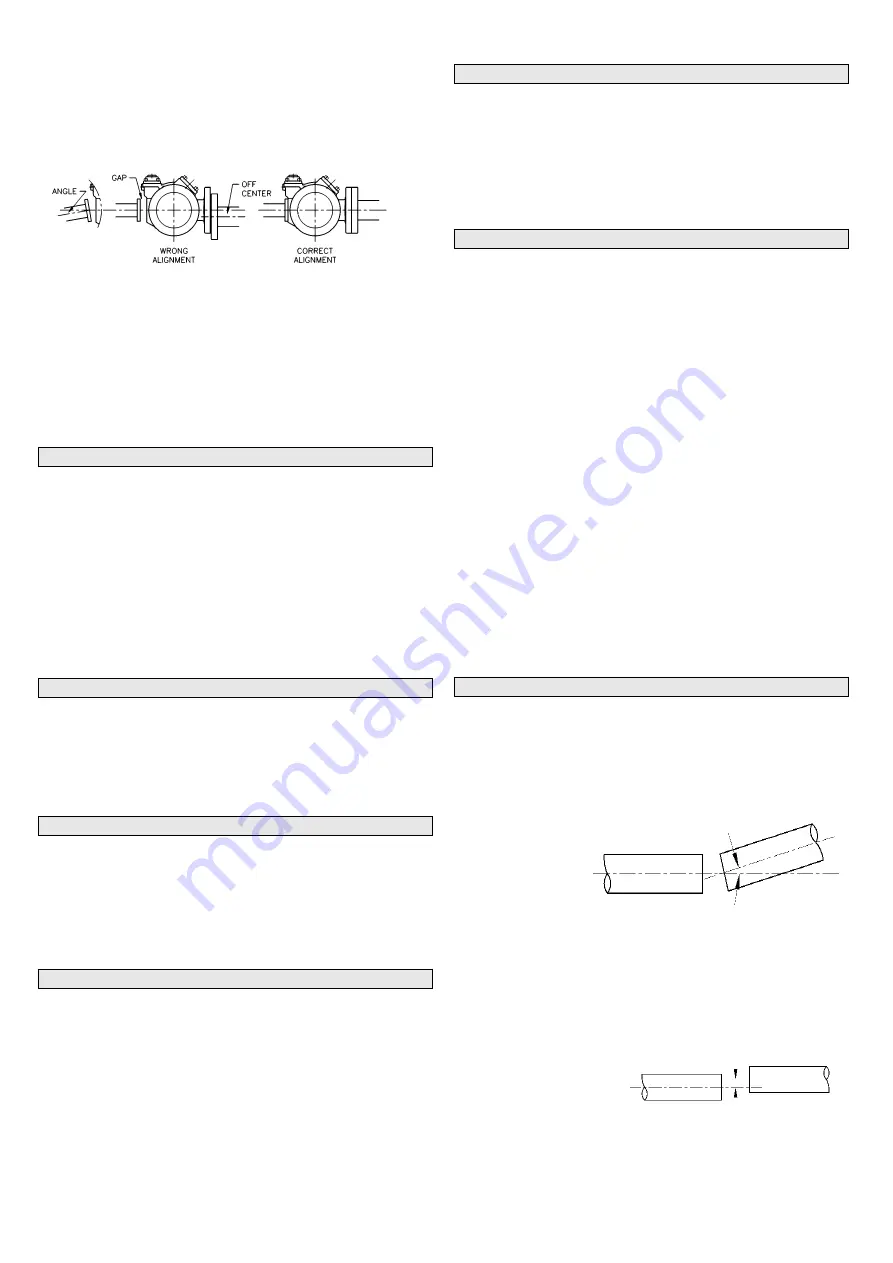

4. Check alignment of pipes to pump to avoid strains which

might later cause misalignment. See Figure 1. Unbolt

flanges or break union joints. Pipes should not spring away

or drop down. After pump has been in operation for one to

two weeks, completely recheck alignment.

NOTE:

Pumps with welded connections contain non-metallic O-

ring seals that will be damaged if welding is done with

these O-rings installed.

Prior to welding the piping, remove the O-rings from under the

alternate inlet flange and discharge flange. After the welding is

complete, reinstall the lubricated O-rings into the cleaned O-

ring grooves.

3.5

R75/R77 - ALTERNATE INLET

The R75 and R77 have an alternate inlet port can be used as a

fill connection for bottom loading of the tank by stationary

pumps at the terminal or bulk plant. It can also be used as an

alternate pump inlet, allowing the pump to unload another tank.

The Alternate Inlet can be used to remove liquid from end user

tanks prior to removal/inspection. As such, it is recommended

that Alternate Inlet must be connected through a suitable

strainer using a minimum 40 mesh strainer screen.

To minimize vapor formation, the alternate inlet line must

minimum DN50 and as short as possible.

3.6

PRE-INSTALLATION CLEANING

NOTE:

New pumps contain residual test fluid and rust inhibitor. If

necessary, flush pump prior to use.

The supply tank and intake piping MUST be cleaned and

flushed prior to pump installation and operation.

3.7

PUMP ROTATION

NOTE:

Confirm pump rotation by checking the pump rotation

arrows respective to pump driver rotation.

The pump rotation is always clockwise looking from the shaft

end. See SECTION 6.1 for instructions for re-handing the

pump.

3.8

CLOSE-COUPLED DRIVES

R75, R77, R80 and R82 pumps are designed to be close

coupled to hydraulic motors and electric motors. The motors

should be well supported with their shafts parallel to the pump

shaft in all respects.

Ebsray can provide optional close-coupled hydraulic motor and

electric motor adapters. These adapters provide straight

alignment of the motor drive through a coupling connected to a

straight key pump shaft.

3.9

LONG COUPLED AND BELT DRIVES

The R80 and R82 pumps are also designed to be long coupled

driven and belt driven.

Long coupled drives should be well supported with their shafts

parallel to the pump shaft in all respects.

Belt drives should be well supported with their shafts parallel to

the pump shaft and should minimise radial load on the pump

shaft.

3.10

PUMP INTERNAL RELIEF VALVE

NOTE:

When fitted, the pump internal relief valve is designed to

protect equipment from excessive pressure and must not

be used as a system pressure control valve or operational

bypass valve.

NOTE:

Non-UL Listed Pumps (e.g. ATEX Marked Pumps) are

normally supplied without the internal relief valve (Blank-

No Valve is marked on the pump). An external pressure

limiting system valve is required for these variants.

For ALL liquefied gas applications, install an external bypass

valve which must have a free and clear passage back to the

tank.

DO NOT pipe the External Bypass Valve back into the

pumps’

inlet line.

External Bypass Valves are vital to the performance and

operation of liquefied gas pumps and control the maximum

operating differential pressure of the system.

If the pump is fitted with an Internal Relief Valve, the

differential pressure setting on the external bypass valve must

not exceed 1400 kPa (14 Bar).

3.11

COUPLING ALIGNMENT

To maximise the life of the pump appropriate alignment of the

coupled shafts is a fundamental requirement of any coupling

installation. If pump was supplied by Ebsray as part of a pumpset

unit, pump and driver have been accurately aligned at factory.

To ensure that alignment has been maintained during transit and

installation,

alignment

MUST

BE

CHECKED

upon

final

installation and prior

to startup.

Ensure

‘distance

between shaft ends’

(DBSE) is correct for the type of coupling utilised.

Angular misalignment

As shown in Figure 2 where shafts are at an angle to one

another should be corrected before parallel misalignment.

Parallel misalignment

As shown in Figure 3

where shafts are in line

angularly and parallel to

each other but are offset

must be corrected.

Figure 1:

Pipe alignment

Figure 2

Figure 3

Summary of Contents for R75

Page 11: ...Publication No 2753 20 11...

Page 13: ...Publication No 2753 20 13...