21

EN

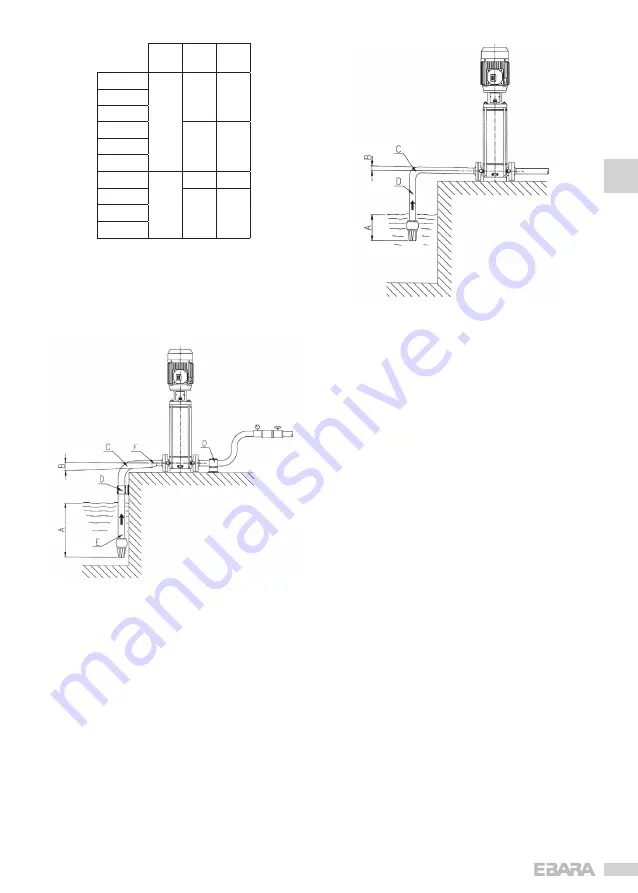

15.6 WARNINGS FOR CORRECT OPERATION OF EVMS MOTOR-DRIVEN

PUMPS (FIG. 1 - FIG. 2)

A

Insufficient immersion

B

Negative slope, air pockets created

C

Tight bend, pressure loss

D

Pipe diameter < pump port diameter, pressure loss

FIG.1

FIG.2

A

Good immersion

B

Positive slope

C

Wide-radius bend

D

Pipework with independent supports

E

Suction pipe diameter ≥ pump port diameter

F

Reducing coupling for eccentric pipes

Model

D

mm

A

mm

B

mm

EVMS1

12

100

180

EVMS3

EVMS5

EVMS10

130

215

EVMS15

EVMS20

EVMS32

14

170

240

EVMS45

190

266

EVMS64

EVMS90

Summary of Contents for EVMS 1

Page 85: ...85 12 13 14 9 8 10 11 A EVMS 1 3 5 10 15 20 3 Nm...

Page 87: ...87 A EVMS 32 45 64 90 without ball bearing 9 10 11 12 13 14 15 5 Nm 2 min...

Page 88: ...88 A EVMS 32 45 64 90 with ball bearing 2 min 1 2 3 4 5 7 6 M8 20 Nm M12 40 Nm M16 70 Nm...

Page 91: ...91 E EVMS 1 3 5 10 15 20 4 kW 1 2 3 4 5 6 7 8 9 10 3 Nm M6 10 Nm 11 12...

Page 92: ...92 E EVMS 1 3 5 10 15 20 5 5 kW 1 2 3 4 5 6 7 8 9 10 11 12 3 Nm M8 18 Nm M10 50 Nm...

Page 97: ...97...

Page 98: ...98...

Page 99: ...99...