5

Section II – Overhaul

A. Unit Removal

WARNING

Turn off all electrical power and relieve hydraulic

pressure. Block any load that could generate

pressure.

1. Remove the unit from the system.

2. Cap all system openings to prevent entry of dirt.

B. Special Tools

The following special tools are needed:

1. Torque wrench rated in lb.in.

2. Flushing plate. Refer to figure 6 for dimensions.

3. 0-500 milliammeter.

C. Improvised Tools

No improvised tools are required for overhaul.

D. Disassembly

Periodic maintenance of the valve will generally not require

disassembly to the extent described here. However, the

sequence can also be used as a guide for partial disassem-

bly. In general, disassembly is accomplished in the item

number sequence shown on Figure 1. Special procedures

are included in the following steps:

1. Thoroughly clean the exterior of the valve.

2. The valve is full of fluid, so hold it over a container

when the cover (3, Figure 1) is removed.

3. Remove parts (1) thru (11) according to sequence.

4. Remove the pilot stage parts (12) thru (26) as a unit

by pulling the adapter (26) from the main stage body (37); at

the same time, push the coil connector from the body. See

Figure 4. Disassemble the pilot stage according to numerical

sequence in Figure 1.

5. Remove parts (27) thru (37).

E. Cleaning

All parts must be thoroughly cleaned and kept clean during

inspection and assembly. The close tolerance of servo

valves makes this requirement more stringent than usual.

Use a commercial solvent which is compatible with the sys-

tem fluid to clean the parts. Compressed air may be used in

cleaning the valve but it must be filtered to remove water and

contamination. Clean compressed air is particularly useful in

cleaning the spool orifices and body passages.

Figure 2. Locating of Adjustment Screw Nuts and Washers

19

18

22

24

23

25

Washer

Lock

Nut

Frame

Nut

Adjusting

Screw

Washer

F. Inspection, Repair, and

Replacement

Check that all internal passages are clean and unob-

structed. Examine all mating surfaces for nicks and burrs.

Check the condition of threaded parts and threaded holes.

Check the retaining ring (15). Minor burrs can be removed

with an India stone.

CAUTION

The spool (33) must not have the land edges broken

with the stone. They are held to a very close

tolerance.

1. Make sure that the 0.020 hole in the side of the spool

(33) and the 0.030 hole in the orifice plug which is screwed

in the end of the spool are completely open. (See Figure 5.)

The orifice plug in the end of the spool may have to be

removed to clean out contaminants that have gathered

inside the spool.

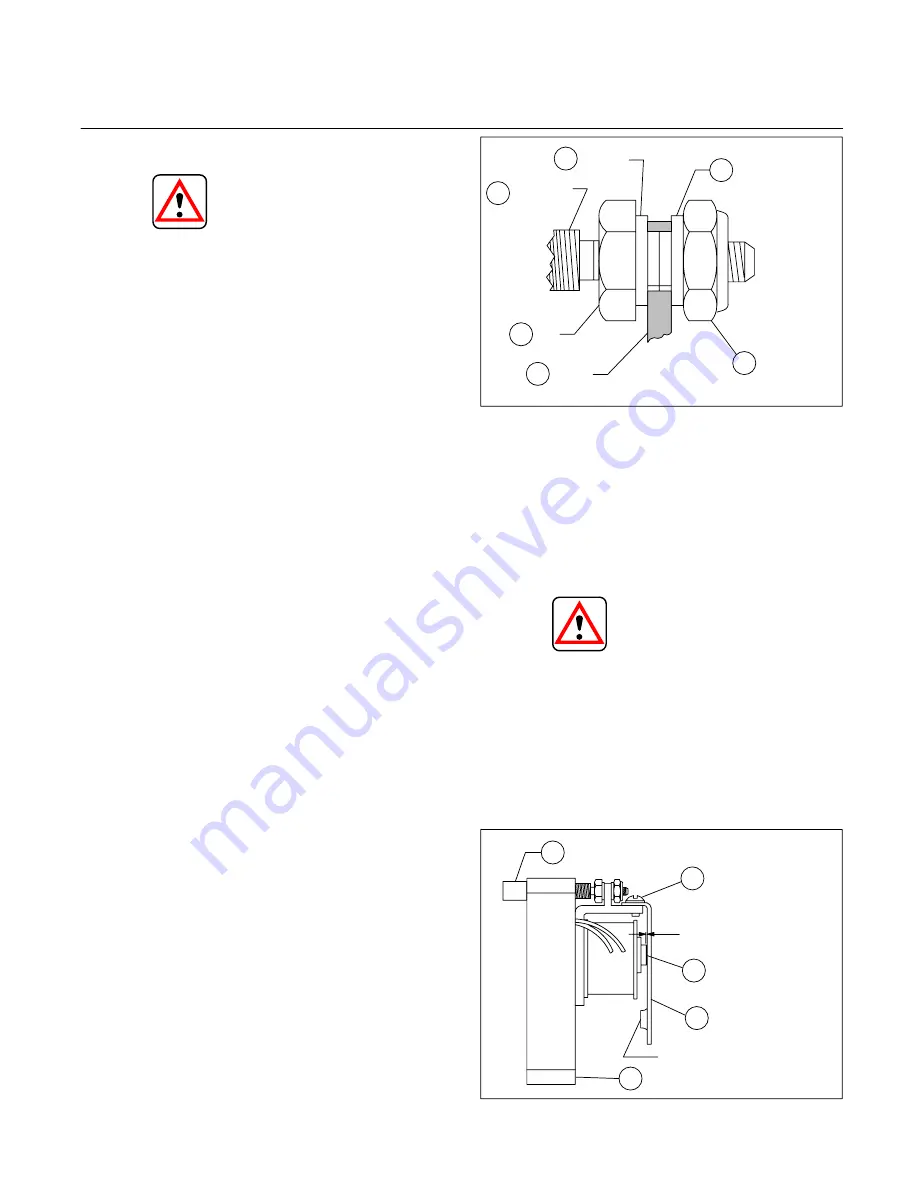

Figure 3. Pilot Stage Servo Valve Adjustment Locations

25

13

26

12

20

Adjusting Screw

Holding Screws

and Lockwashers

0.010 Clearance

Nozzle

Flapper Armature

Adapter S/A

Extrusion