8

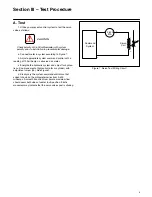

Figure 6. Flushing Plate

3.00

1.438

2.130

2.120

1.067

1.057

2.44

0.943

0.933

0.943

0.933

0.312

0.536

0.526

1.567

1.557

1.817

1.807

0.2812 Drill thru

4 holes

0.4219 Drill - 2.72 deep

1/4 NPT thread

1.000

Stock

0.844

0.610

0.615

Dia.

3 Places

0.015 R

Max.

0.045

0.050

63

0.500

0.4219 Drill - 0.53 deep

counterbore as shown -

3 holes

1.438

0.500

0.4219 Drill - 2.12 deep

1/4 NPT thread

Material:

Free machining

low carbon steel

Surface finish:

125 except where specified.

H. Unit Installation

Flush the system through 10 micron full flow filters prior to

installing the servo valve. A flushing plate can be manufac-

tured. (See Figure 6.) The plate passes the fluid directly to

the tank port. Continue flushing until new filters show no sign

of contamination. It may be necessary to change the system

fluid. If so, filter the new fluid as it is poured into the reservoir

and then flush the system as described above. After the

system is flushed, remove the flushing plate and install the

servo valve. Torque the mounting screws to a maximum of

112 lb.in.