Exercise 2: More Logic Instructions

This exercise covers other basic functions like Set/Reset, MCS/MCR and Compare.

Use case: An injection mold machine has an automatic refiller for the plastic pellet reservoir. At the

beginning of the shift, the operator approaches the machine and presses the start button. The

filling mechanism automatically keeps the level in the reservoir between 10 and 100 lbs. If the

filler is already running, the operator has the opportunity to press a button that engages the filler

at a higher speed to fill the reservoir quicker.

•

We’ve already created the cycle start command (M0); an output that will turn on a lamp that indicates the fact

that the machine is running (Y0); and an e-stop reference (M1).

•

We will be adding 4 rungs in this exercise. To insert rows, right click in the space between the first rung and

the end statement and choose Insert Row.

TIP: If you can’t choose Insert Row, you may still be in Ladder Monitoring Mode! You can toggle in and out

of this mode by clicking the button in the toolbar.

•

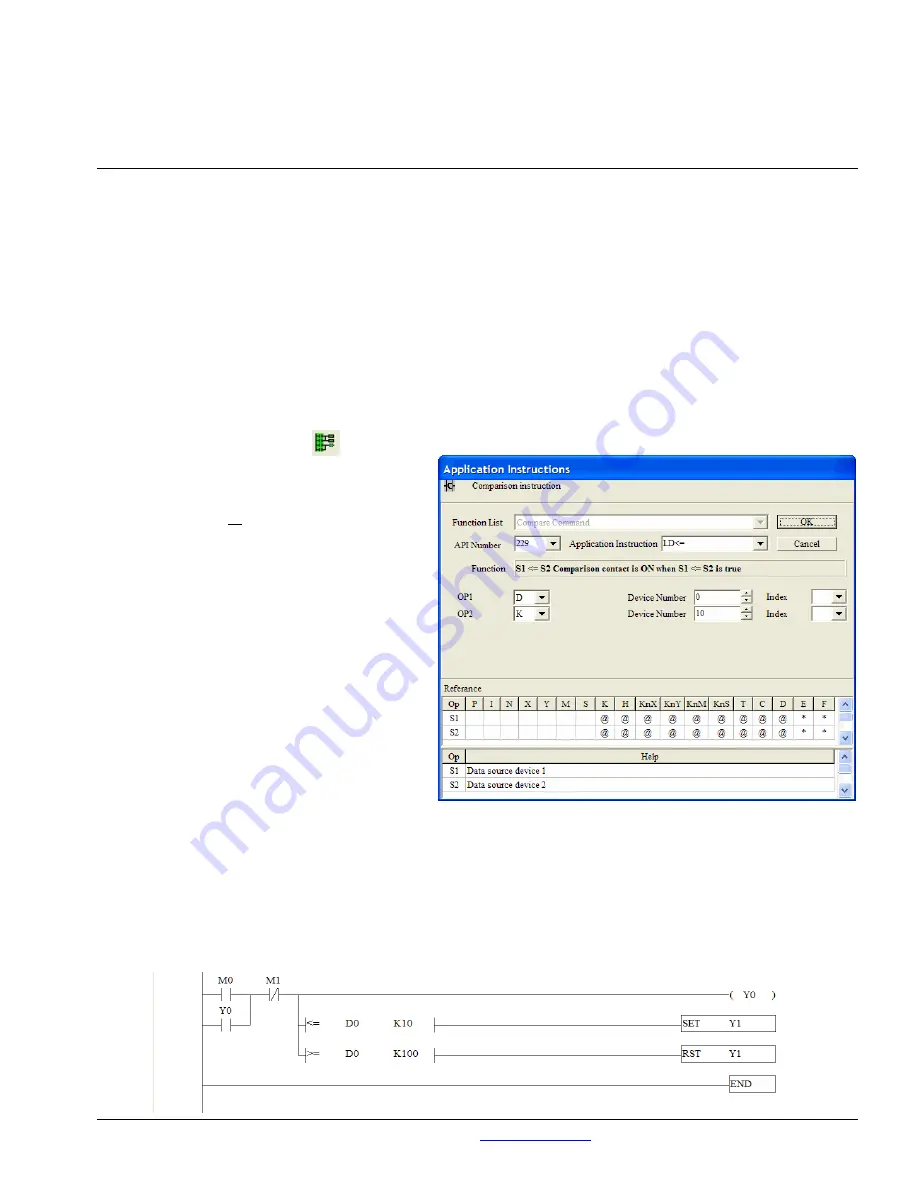

Just below the first rung and to the right of

the M1 contact, either type LD<= and click

the ellipsis button on the Input Instruction

Popup window or click the Application

Instruction tool on the toolbar and choose

LD<= from the pull down arrow next to

Application Instruction. The window to

the right will appear.

TIP: Get to know this window! The better you

understand this window, the easier it will be

for you to program your ELC. When you

use an advanced function block in ELCSoft,

this window is a big help in deciphering how

the program works. For each Application

Instruction that you choose in this window,

there is a specific description of its function

in the “Function” window.

•

We will be storing the weight of the reservoir

in word D0. Since we want the motor on

when the wieght is at or below 10, we’ll set the OP1 window to D, the corresponding Device Number to 0, and

leave the Index window blank. The OP2 window will be K to represent a constant decimal value, the Device

Number will be 10 (our minimum) and Index will again be blank.

•

The output on this rung will be a SET instruction with Y1 as its reference (to turn on the “fill mechanism”).

Either type SET Y0 and press enter, or use the Application Instruction window, choose the SET instruction,

and enter Y and 1 respectively.

•

Repeat the last 3 steps just below the rung you’ve been working on to create a rung that resets (RST) Y1

when the value of D0 is equal to or greater than 100. These two rungs should look somewhat like this:

Pub. No. TR05003001E

For more information visit:

www.EatonElectrical.com

19