I.B. 48003

Page 17

Effective 11/97

CONTACTOR MAINTENANCE

All work on this contactor should be done with the main

circuit disconnect device open, and using a separate

source of control power to operate the magnet. Before

applying external control circuit power, make certain that

the contactor coil circuit is electrically isolated, to prevent

feedback into a control power transformer that could be

hazardous. Disconnect power from any other external

circuits. Also, discharge any hazardous capacitors.

The basic principles to be followed in the maintenance of

all electrical equipment are: (1) keep conducting parts as

good conductors and (2) keep insulating parts as good

insulators, i.e., tighten and clean.

Much routine maintenance on the low-voltage portion can

be done with the contactor partially withdrawn to the

balanced position, rather than completely removed.

However, the contactor can also be completely removed

and taken to a bench.

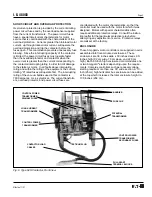

A bottle wrench and a .020-inch (.51mm) feeler guage

are screw-mounted to the right-hand sidesheet of the

contactor when the Ampgard

®

controller is shipped. The

feeler gauge is used to determine the vacuum bottle end-

of-life by virtue of contact erosion. One end of the bottle

wrench is used to adjust the operating arm associated

with the Type L64 auxiliary contacts (see Auxiliary

Contact Adjustment below) and the other end of the

wrench is for use with pre-1983 vintage vacuum bottles.

Insulation Level

Refer to the insulation resistance measurements between

contactor poles and from each pole to ground that were

recorded at start-up and subsequent intervals. Measure

the same points in the same manner and record. Investi-

gate any abrupt reduction in resistance or any unusually

low reading.

Dust and moisture are detrimental to electrical equipment

and industrial equipment is designed to tolerate a less-

than-perfect environment. However, excessive dust can

cause trouble, and should be wiped or blown off at appro-

priate intervals. If the contactor is wet for any reason, dry

it until the insulation resistance between poles and from

each pole to ground has returned to normal.

The contacts inside the interrupters are immune to dust

and moisture and require no attention of this type.

Vacuum Interrupters

Gross loss of vacuum is highly unlikely, but it can be

checked easily. With the contactor open, pull upward on the

bottle nuts, one pole at a time, using an effort of about 20

pounds (9 kilograms). If the bottle nuts move easily away

from their pivot, the vacuum has probably failed and the

bottle sub-assemblies must be replaced.

It is also unlikely, but possible, to have a very slight leak

that does not change the bottle force appreciably, but

which might seriously damage the ability of the bottle to

interrupt. In this regard, it must be remembered that in

a three-phase circuit, it is possible for any two good

interrupters to successfully interrupt the circuit even if

the third interrupter is weak. But this condition should

not be allowed to continue. It can be detected only by a

dielectric test.

Check the dielectric strength of the interrupters before

the contactor is energized for the first time and regularly

thereafter to detect, at the earliest possible date, any

deterioration in the dielectric strength of the contact gap

since this may result in an interruption failure. The

vacuum interrupters should be tested as specified in the

section CHECK-OUT, VACUUM INTERRUPTERS.

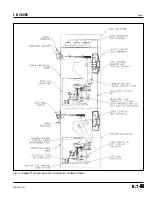

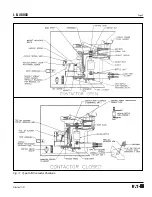

Fig. 14 Controller With Doors Open