3

Instruction Booklet

IB48050

Effective September 2012

Instructions for installation,

operation, and maintenance of the

AMPGARD 15 kV, 300A vacuum starter

eaton Corporation

www.eaton.com

Ratings

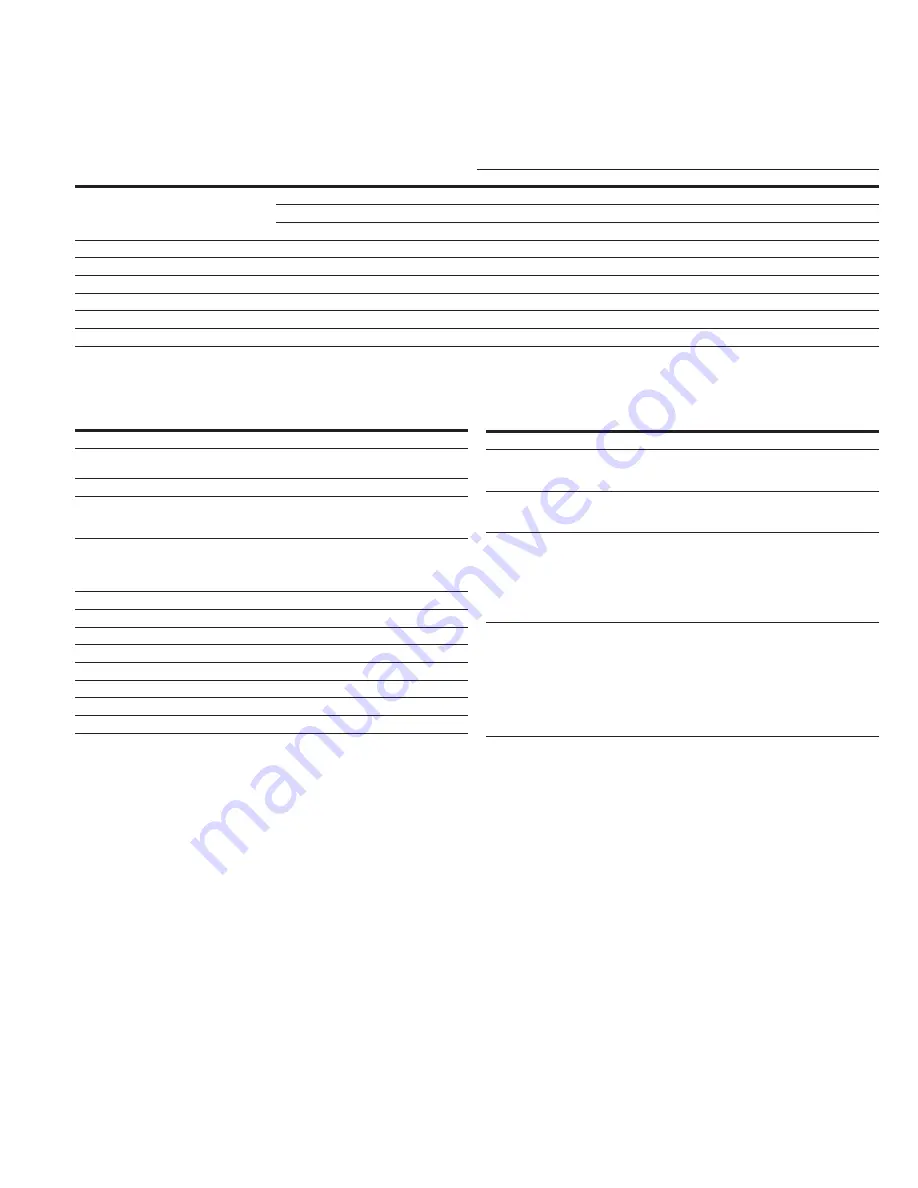

Table 1. Starter Ratings

Description

Utilization Voltage rating

10,000 to 11,000V

12,400 to 13,800V

Interrupting rating

E1 (unfused)

5 kA

5 kA

E2 (fused)

950 MVA at 11,000V

1190 MVA at 13,800V

E2 (fused)

63 kA

63 kA

Continuous current

300A

300A

Induction motor

6000 hp

7500 hp

Synchronous motor (0.8 PF)

6000 hp

7500 hp

Synchronous motor (1.0 PF)

6750 hp

8500 hp

Transformer

5400 kVA at 11 kV

6800 kVA at 13.8 kV

BIL

75 kV

95 kV (with arrestors)

Table 2. SL Contactor Ratings

Description

rating

Maximum voltage

15,000V

Maximum interrupting current

(three operations)

5000A

Rated current

300A enclosed/300A open

IEC make-break capability

AC3—Make

AC3—Break

3200A

2560A

Short time current

30 seconds

1 second

8.75 milliseconds

1920A

4800A

25 kA peak

Mechanical life

1 million operations

Electrical life

100,000 operations

Dielectric strength (60 Hz)

36 kV (1 minute)

Closing time

80 milliseconds

Opening time

130 to 330 milliseconds (selectable)

Weight

95 lbs (43 kg)

Arcing time

12 milliseconds (3/4 cycle) or less

Pickup voltage

80% rated coil voltage

Description

rating

Dropout voltage

60% rated coil voltage

Control voltages

AC

DC

110/120/220/240V (50/60 Hz)

125V

Control circuit burden (rated volt)

Closing

Holding

2600 VA

80 VA

Auxiliary contact ratings

Voltage (maximum)

Continuous current

Making capacity (AC)

Making capacity (DC)

Breaking capacity (AC)

Breaking capacity (DC)

600V

10A

7200 VA

200 VA

720 VA

200 VA

Latch (when specified)

Mechanical life

Trip voltages (DC)

Trip voltages (AC)

Tripping voltage

Tripping burden

24 Vdc

48 and 96 Vdc

110 and 220 Vac

250,000 operations

24/48/96V

110/220V (50/60 Hz)

80% rated coil voltage

1200 VA

400 VA

500 VA

Ratings are based on full voltage starting of standard motors

with locked rotor current equal to 6-times full load current and

an acceleration time of 10 seconds . The starter may be supplied

with a definite purpose rating of up to 300A depending on the

type of starting (reduced voltage autotransformer for example),

locked rotor current, and acceleration time . Consult the factory

for more information .

Starters are supplied with bolt-in main fuses . Contactors have

stab-in connections to the starter cell .

The flow of current through a starter with bolted fuses and a

stab-in contactor can be described as follows: The line finger

assembly mounted at the back of the enclosure serves to connect

the isolation switch moving stabs to the controller line terminals

when the switch is closed . Power flows from the switch moving

stabs through two flexible shunts to the upper fuse mountings .

The fuses are connected to the lower fuse mountings that contain

the line-side stab connections to the line finger assemblies for the

main contactor . With the main contactor energized, power flows

through the contactor’s vacuum interrupters to the contactor load

fingers, which are engaged on to the controller load-side stabs .

Medium voltage cables connect the load-side stabs to the motor

load connections . The contactor is held in place by a set of rails

mounted in the lower part of the cell . For full-voltage starters, the

motor load connections are mounted to the left of the main fuses

in the rear of the compartment, facing forward . For reduced voltage

starters, the motor load connections are mounted in the left rear

of the reduced voltage structure . Current transformers are typically

mounted just below the motor load connections .