1

2

5

1

25

STRUCTURE OF HOT WATER

PRODUCTION SYSTEM

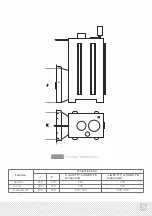

In the system of hot water production there are 2 main elements: heat-exchange unit (point

1) and water receiving tank (point 2) connected by pipes.

Heat-exchange unit is a rectangular tank with a volume of 3,5 liters. Its function is heating

up of water by receiving heat of the furnace. The heat-exchange unit is attached directly to the side

wall of the furnace. There are one inch threaded joints (points 3 and 4) on the top and on the bottom of

the heat-exchange unit that connect pipe-lines to the side-mounted tank.

Heat-exchange unit is a structural section of the furnace. When the furnace is heated up, it is not

allowed to fill up the system if there is no water in the water level gauge of the side-mounted

water receiving tank.

Constant exploitation of the system without water is not permitted because it leads to short life of

a furnace.

Side-mounted water receiving tank is a rectangular, cylindrical or di erent shape reservoir

(shape and dimensions can vary based on customers wishes and technical peculiarities of the

installation site). At the top of a tank there is a tank fillet pipe (point 5) which is needed to fill the system

with water, with a hermetic lid (point 6) and one inch threaded joint (point 7) for steam removal from

indoor space. There are one inch threaded inlet and outlet joints (points 8 and 9) at the bottom of a

tank. The hot water faucet (point 10) is on the front wall of a tank. All water receiving tanks are

equipped with water level gauges which allow monitoring water level while in operation.

Fill the tank with water not exceeding upper point of the water level gauge.

The heat-exchange unit and water receiving tank are connected by metal pipes (points 11 and 12) one

inch in diameter. There is a T-tube (point 13) with connected discharge pipe on the bottom tube which

allows discharging water system via faucet (point 14) in wintertime.

In circumstances when the distance between heat-exchange unit and water receiving tank is

less than 1 metre, when water level lowers while in use or when the furnace burns for more than 3

hours, water can start boiling. Water boiling goes along with insignificant noise.

To prevent boiling add some cold water in the system (if water level lowers when in use).

Choose water receiving tank based on assumption that there's should be 15 litres per person plus 10

litres to steam the bath besom.