20

The space between the two rubbers is adjusted in working state. In stand-by

state, the unbalance of space between the two rubber rollers is produced by the screw

pitch of the stroke adjustment structure, which does not affect normal operation. If

the quality of lamination is affected, check and adjust according to the following steps:

·

Open the right and left cabinet covers;

·

Check if the left and right pressure adjustment pedestals are loosened. If

so, adjust the pressure adjustment pedestals and tighten them;

·

Check to see if the longitudinal bevel gears on both sides are loose. If the

left is loose, open the gear and take down the screw of pressure-regulat-

ing support. Tighten the screw at the gear top with a wrench after tilt

the transverse bevel gear. Then fix the parts in where they were. If the

right longitudinal bevel gear is loose, it is not necessary to dismantle

the transverse bevel gear. The other checking steps are the same as for

the left side.

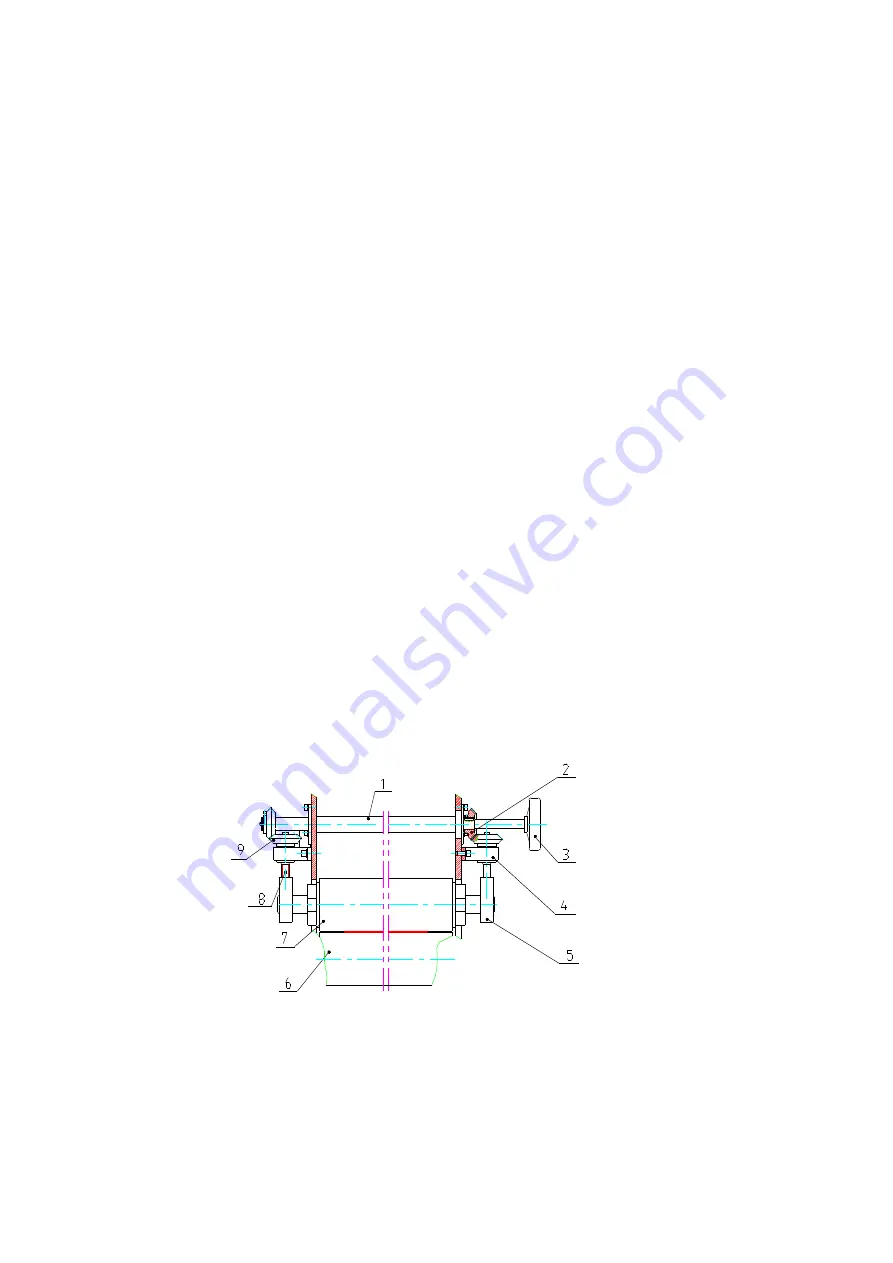

· How to adjust the space between the two rollers: ( Please see Figure 13 )

1)

Place a piece of photo-printing paper between the two rubber rollers with a moderate

length (150mm narrower on both sides than the film). Turn the pressure-regulating

hand-wheel so that the top roller contacts the paper. Apply slight pressure and observe

with eyes if the space between the rollers on both sides of the photo-printing paper is the

same.

2)

If the space is uneven, dismantle the transverse bevel gear on the left side. Turn the

longitudinal bevel gear until the space becomes even according to the actual space

needed.

3)

Install the left transverse bevel gear and baffle piece, and tighten the screws of all the

parts.

1. Linkage shaft 2. Transverse bevel gear 3.Pressure-regulating hand-wheel

4.Pressure-regulating support 5. Pressure-regulating block 6. Bottom roller

7. Top roller 8. Pressure-regulating position shaft 9. Longitudinal bevel gear

( Figure 13 )