Installation, Operation and Parts Manual

EE-6214EKZ

22

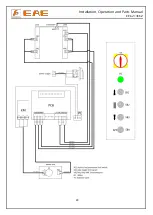

5.3 Operation instructions

To avoid personal injury and/or property damage, permit only trained personnel to operate the lift. After reviewing these

instructions, get familiar with lift controls by running the lift through a few cycles before loading vehicle on lift. Always lift the

vehicle using all four adapters. Never raise just one end, one corner or one side of vehicle adapters. The lift must be o nly used in a

static position for lifting and lowering vehicles.

POS.

Name

Function

QS

Main switch

Control main power

HL

Power indicator

Show if electricity is connected

SB1

UP button

Control the rising movement

SB2

LOCK button

Engage mechanical lock

SB3

DOWN button

Control the lowering movement

SB4

APS button

Push APS button to lower the carriage

directly, on condition that the lock is not

engaged.

Only one operator is allowed to work around the vehicle lift.

Always engage the safety locking mechanism before any operation on the lifted vehicle.

Do not make any operation on the lifted vehicle at a height under the first latching position (less than 500mm).

Never attempt to lower the lifted vehicle to the bottom when

Any of its wheel is removed unless you are assured that no damage will occur.

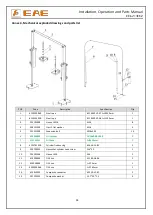

Raise the lift

Make sure vehicle is neither front nor rear heavy and center of balance should be midway between adapters and centered over t he

lift.

1. Park the vehicle between two posts.

2. Adjust the lifting arms until lifting trays are under the pick-up positions of the vehicle and make sure the gravity of vehicle located over

the center of four lifting arms.

3. Turn on the Main power switch.

4. Push the”UP”button on the control box until lifting trays have touched the pick-up positions of vehicle.

5. Keep on raising the vehicle making its wheels have a bit clearance off the ground and check again the stability.

6. Raise the vehicle to the excepted height, push the “Safety Lock” button to engage the mechanical safety lock. Check again the stability and

then perform maintenance or repair work underneath.

Lower the lift

When lowering the lift pay careful attention that all personnel and objects are kept clear.

1. Push the “DOWN” button on the control box. Initially the carriages will go upwards about 5CM to release the safety lock. After that the

carriage starts descending. .

2. When the lift is fully lowered, position the lift arms and adapters to provide an unobstructed exit before removing vehicle from lift area.

3. Drive the vehicle away.

APS function

In the case the mechanical locking unit is released, push APS button and DOWN button for direct lowering.