5

Anchor Screws

Controls

Control Wiring

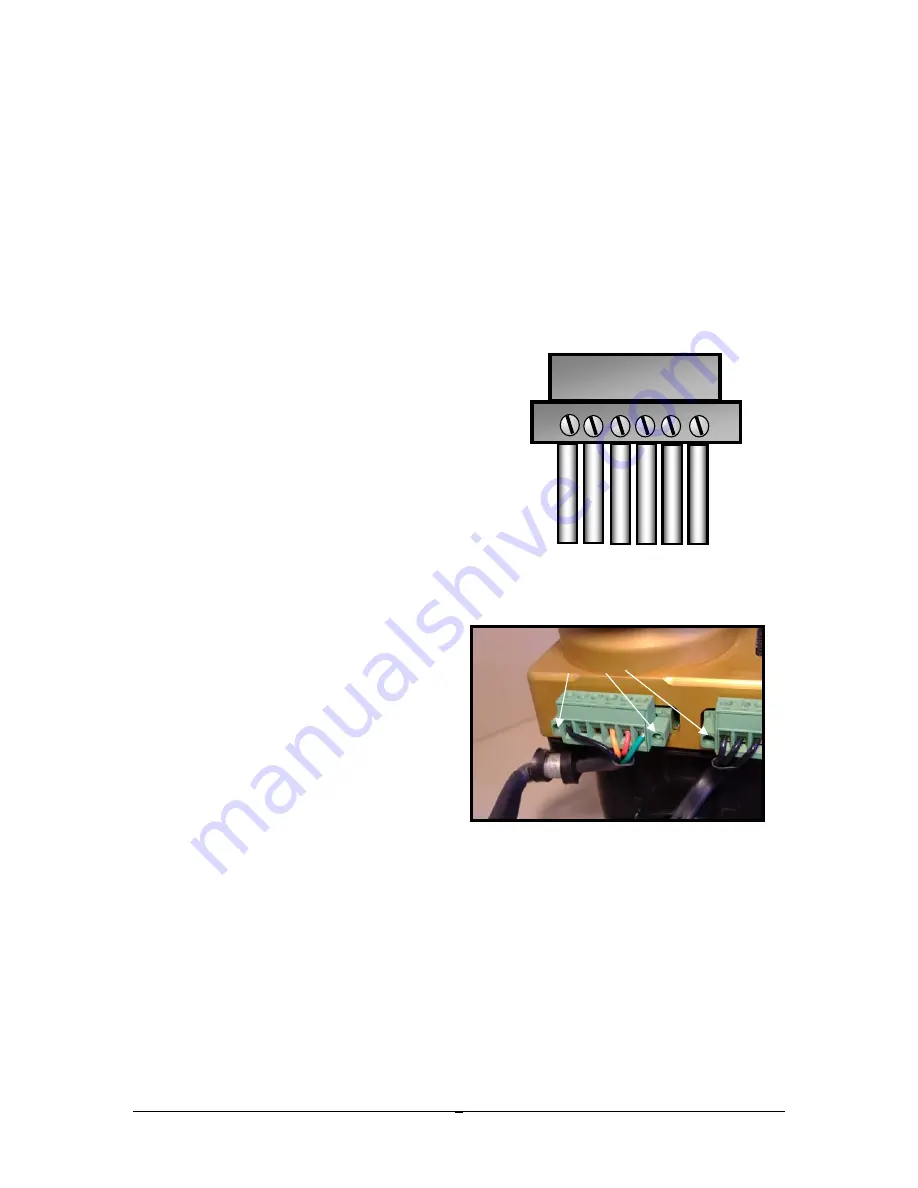

– Control leads are connected to the ignition via a Control Plug that

captures each lead with a screw cage mechanism. The plug is then attached to the

ignition and secured with anchor screws on either side. A wiring diagram is included

at the end of this manual. The numbering system for the plug terminals is 1 thru 6 as

viewed looking at the cage screw heads with wires oriented below (see fig). The

wire/plug assignments are as follows

:

Use the cushioned anchor strap to provide a

mechanical strain relief for the wires.

1.

“1” connects directly to a nearby

engine case ground using 18 gauge

wire.

Note 1: You cannot rely on the

ignition’s mechanical attachment to the

engine to provide ground. Aluminum

anodizing acts as an electrical

insulator, so the clamp connection to

the anodized flange will not serve as a

reliable ground.

2.

“2” Control Alternate (future use)

3.

“3” Control Alternate (future use)

4.

“4” connects to your ignition

ON/OFF (ground) p-lead switch

using 20 gauge wire or larger.

Note 1: If you are replacing a

magneto, your old P-Lead can

serve this purpose, and may

already be wired to a suitable

switch. Note 2: Non-starting

magnetos require a mechanism to

prevent them from firing during

start-up. Keyed ignition switches

have a jumper on the back that serves this purpose. When installing an E-

MAG in place of a non-starting magneto that was controlled by such a

switch, make sure you remove this jumper. You do NOT want a start-up

block on any circuit controlling your E-MAG(s).

5.

“5” connects to your main 12 volt aircraft buss through a dedicated circuit

breaker (not provided) using 18 gauge wire. E-MAGs should use a 5-amp

breaker, and P-MAGs should use a 3-amp switchable breaker. The

switch is needed to test the P-MAG internal alternator during ground run

up – see Operating Notes.

Note 1: Whenever the aircraft buss is

powered up, the ignition is “awake”. It draws a small amount of current

Tack

1

Control Plug

4

5 6

3

A

L

T

2

A

L

T