BlueWave® MX-MIM User Guide

33

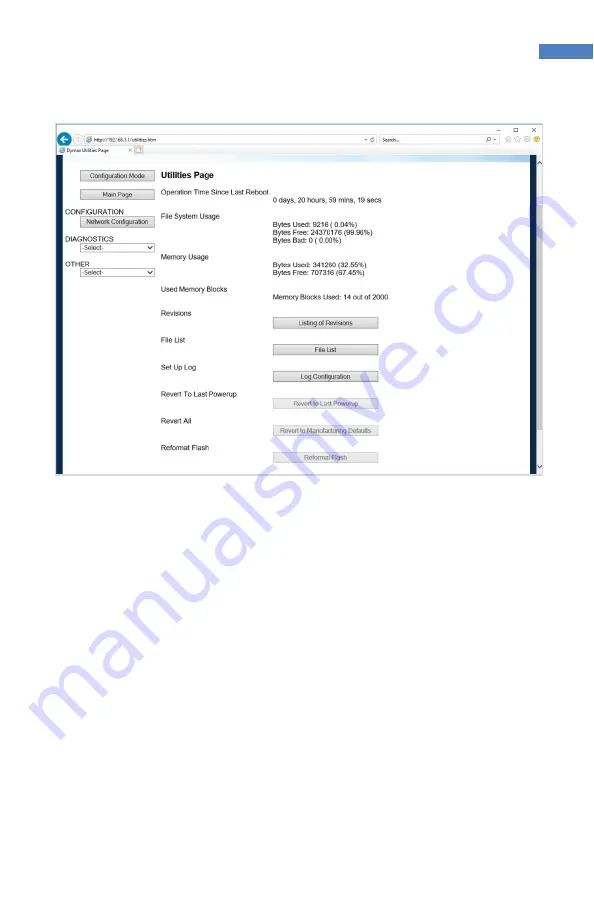

Figure 30. Utilities Page

Log Configuration

Enable:

Enable or disable the logging feature.

Log Size:

Total number of log messages that will be captured.

Start Log Size:

Total number of log messages to always display. If set to

250 and log size is set to 1000, then the first 250 logs will

always be displayed and the remaining 750 will be the

most current 750 logs available.

Task Log Configuration:

Each task listed below represents a different process the

product has. You have the ability to turn on certain

capture filters that the diagnostics logging page will

display. Each bit within the 16-bit value displayed

represents a different capture filter.

Bit 0: Start Up

Bit 1: Error

Bit 2: Event

Bit 3: Assertion

Bit 4: BSP Comms Bit 5: Prot Comms

Bit 6: dbprintf

Bit 7: Alarm

Bit 8..15: Reserved