22

ZERO-CLEARANCE FIREPLACE

INSTALLATIONS

1. Manufacturer’s Instructions:

Carefully

read and comply with the manufacturer’s

installation instructions for your fireplace. Be

sure that DuraTech is approved for use with

your appliance.

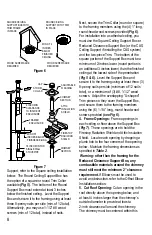

2. Anchor Plate:

Attach an Anchor Plate

to the fireplace top with (4) 5/8” sheet metal

screws

(Fig 31)

. Check with the appliance

manufacture about the use of high temperature

sealants.

3. Chimney Sections:

Attach a Chimney

Section to the Anchor Plate by twist-locking

clockwise.

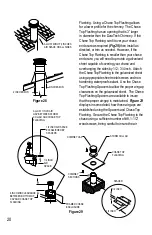

4. Completion:

Install the remainder of the

chimney as instructed for a standard Ceiling-

Supported installation, (using a Firestop

Radiation Shield in the 1st floor ceiling instead

of the Support Box). Always maintain at least

2 inches of clearance to combustibles, and

enclose the chimney where it passes through

occupied areas.

CONNECTION FROM APPLIANCE

TO CHIMNEY SYSTEM

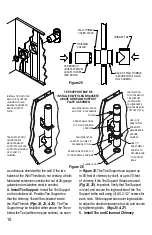

1. Single Wall Stovepipe:

If single wall stovepipe

is desired, DuraVent’s “DuraBlack” single-wall

stovepipe is recommended. The connection

to the Ceiling Support Box, or Finishing Collar

is made with a DuraBlack Slip Connector or a

Snap-Lock Adapter. The beaded end of the Slip

Connector or Snap Lock Adapter slips into the

opening in the Ceiling Support or Finishing Collar.

Align the tabs on the Slip Connector or Snap

Lock Adapter with the notches in the face of the

Support Box or Finishing Collar, push it in and

rotate to lock it in place. Further instructions for

assembling DuraBlack Stovepipe are contained in

their shipping cartons. Remember, the minimum

clearance to combustibles for single wall stovepipe

is 18 inches.

2. Close Clearance Connector Pipe (DVL):

DuraVent manufactures a close clearance

connector pipe, also referred to as “DVL”. DVL

may be positioned as close as 6 inches to a

combustible wall, and as close as 8 inches to

a combustible ceiling, provided the appliance

installation instructions permit this distance. In

order to join this type of connector to the Support

Box or Finishing Collar, a DVL/DuraBlack Chimney

Adapter is required. The DVL/DuraBlack Chimney

Adapter slips into the opening in the Support Box

Figure 30

Figure 31

ANCHOR

PLATE

MASONRY

ANCHOR BOLTS (4)

REQUIRED

(NOT FURNISHED)

EXISTING

MASONRY

CHIMNEY

WITH LEVELED

SURFACE

HIGH TEMP

SEALANT

MAINTAIN 1 INCH MIN

CLEARANCE FROM ANCHOR

PLATE TO COMBUSTIBLES

SHEET METAL

SCREWS

(4 REQUIRED)

CHIMNEY

SECTION

ANCHOR

PLATE

NOTE:

Follow local

building code

requirements

for connecting

factory-built

chimney to

masonry

fireplaces.