17

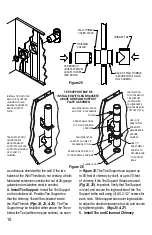

as needed to fit your installation. There are

two options when installing a Tee-Supported

installation: the Tee Support above the Tee, or

the Tee Support below the Tee. The required

parts and general configuration are as shown

in

Figures 23, 24, 25 and 26

.

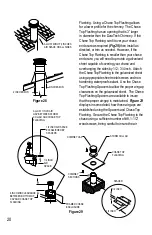

1. Place Appliance:

Position the appliance

according to the manufacturer’s instructions. It

is a good idea to try to position the appliance

so it will allow the chimney to line up centered

between studs.

2. Locate, Cut & Frame Opening:

Determine

the location where the chimney will pass through

the wall. The chimney should pass through

the wall, centered between two studs. The

height of the penetration can be determined

by positioning sections of stove pipe until you

have the desired configuration (refer to the

appliance manufacturer’s installation instructions

for restrictions on stove pipe). Cut and frame

an opening in the inner and outer walls at this

location. Refer to

Table 2

for the appropriate

framing dimensions.

3. Install Wall Thimble:

The Wall Thimble

is two-piece component which includes the

Interior half and the Exterior half. On the

outside wall, install the back portion of the Wall

Figure 23

Figure 24

Thimble. Center the back portion of the Wall

Thimble (with shield inside wall) in the framed

opening of the outside wall. Be sure to seal

the flange of the Wall Thimble around the wall

by using a non-hardening waterproof sealant.

Attach the back portion of the Wall Thimble to

the outside wall using at least (4) 8-penny nails

or (4) #8, 1-1/2” wood screws. There must be

MIN 6 INCHES

CLEARANCE

BETWEEN CAP AND

CHASE TOP

ACCESS DOOR

FOR CLEANING

CHASE TOP

FLASHING

FRAMED EXTERIOR

ENCLOSURE

TYPICAL THRU-

THE-WALL TEE

SUPPORTED

INSTALLATION

FINISHING COLLAR

TEE CAP

CHIMNEY SECTION

CHIMNEY TEE

USE 8 PENNY NAILS OR #8, 2 1/2” WOOD

SCREWS. USE 4 FOR EACH SUPPORT

LEG.

TEE BRANCH (MUST

PENETRATE A MINIMUM

OF 6 INCHES INTO ROOM)

WALL THIMBLE

ASSEMBLY

TEE SUPPORT IS ADJUSTABLE TO

ALLOW FROM 2” - 6” CLEARANCE FROM

CHIMNEY TO WALL.