18

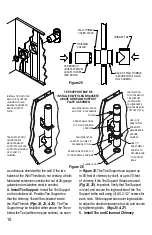

a continuous shield within the wall. If the two

halves of the Wall Thimble do not overlap, a field-

fabricated extension constructed out of 26-gauge

galvanized or stainless steel is needed.

4. Install Tee Support:

Install the Tee Support

on the outside wall. Position Tee Support so

that the chimney Tee will be centered inside

the Wall Thimble

(Figs 24, 25, & 26)

. The Tee

Support may be installed either above the Tee or

below the Tee (within one pipe section), as seen

in

Figure 26.

The Tee Support can support up

to 50-feet of chimney by itself, or up to 70-feet

of chimney if the Tee Support Straps are used

(Fig 24, 26)

. Important: Verify that Tee Support

is level, and secure the leg brackets of the Tee

Support to the wall using (4) #8, 2-1/2” screws for

each side. Slide support base over leg brackets

to adjust for desired clearance to wall, and secure

by tightening bolts.

(Figs 26 & 27)

.

5. Install Tee and Cleanout Chimney

Figure 25

Figure 26

INSTALLATION

WITH TEE BELOW

TEE SUPPORT

(SHOWN WITH

LEG BRACKETS

MOUNTED BELOW

SUPPORT PLATE)

USE 1/2”

SHEET METAL

SCREWS TO

SECURE BAND

TO SUPPORT

BASE

USE (4) 1/2”

SHEET METAL

SCREWS TO

SECURE BAND

AROUND

CHIMNEY

WALL THIMBLE

COVER PLATE

FINISHING

COLLAR

TEE BRANCH

(MUST EXTEND AT

LEAST 6 INCHES

INTO ROOM)

CHIMNEY TEE

BACK OF WALL THIMBLE

(SECURE WITH 4 NAILS

OR 4 SCREWS)

CLEANOUT CAP

INSTALLATION WITH TEE

BELOW TEE SUPPORT

(SHOWN WITH LEG

BRACKETS MOUNTED

ABOVE SUPPORT

PLATE)

TEE SUPPORT WITH

LEG BRACKETS

MOUNTED ABOVE

SUPPORT PLATE CAN

SUPPORT A MAXIMUM

OF 50-FEET OF

CHIMNEY.

TEE SUPPORT MAY BE

INSTALLED WITH LEG BRACKETS

ABOVE OR BELOW SUPPORT

PLATE AS SHOWN

8-PENNY NAILS OR #8, 2 1/2”

WOOD SCREWS, 4 PER SIDE

ADJUSTABLE TEE

SUPPORT ALLOWS 2”-6”

CLEARANCE TO WALL

ADJUSTABLE WALL STRAP,

ALLOWS 2”-6” CLEARANCE

TO WALL

8-PENNY NAILS OR #8,

2 1/2” WOOD SCREWS,

2 PER SIDE