12

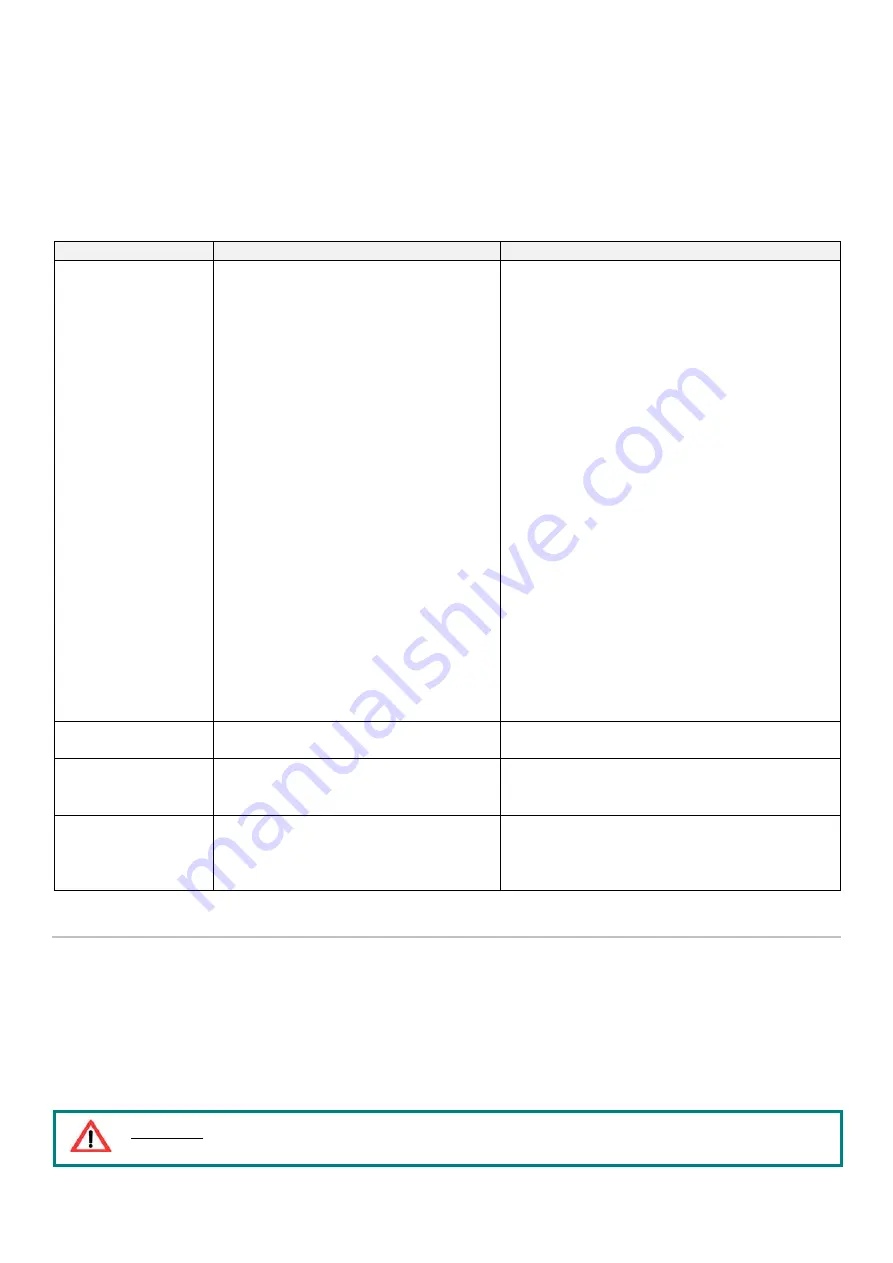

A diagnostics table is provided below that indicates the main anomalies, the probable causes and the possible solutions.

If you were not able to solve the problem after consulting the diagnostics table, do not try to find the fault by disassembling

machine parts but contact the Dropsa technical office and report the anomalies that have been discovered, with a detailed

description.

PROBLEM

CAUSE

SOLUTION

The electric pump does

not deliver lubricant.

The electric motor is not operating.

The tank is empty.

The pump does not prime. Cause for the

pump not priming:

•

The motor is rotating in the inverse

direction (clockwise);

•

The motor is rotating in the correct

direction, but the spatula is not rotating;

•

Air bubbles in the lubricant.

The pressure control valve (bypass) was

calibrated at a value that is too low

Presence of dirt in the non-return valve

Check the connection between the motor and the

electric power supply line.

Check the motor windings.

Check that the motor terminal board connection

plates have been positioned according to the power

supply voltage.

Fill the tank.

Attention: if the tank emptied itself and the electric

signal indicating that the minimum level was reached

was not given, check the minimum level contact.

Remove the tank cover and check that the spatula

rotates clockwise and moves the lubricant; otherwise,

invert two of the three motor phases.

See above.

Disconnect the pump delivery pipe and bleed the

lubricant until the air bubbles have been eliminated.

The pump does not

pressurise.

There may be dirt on the pumping element

check valve cone.

Clean the pumping element check valve cone and

seat, bleeding the lubricant.

No minimum level

signal when there is no

lubricant in the tank.

Minimum level incorrectly regulated.

Check the correct operation of the level probe as

follows:

Check the correct level adjustment of laser probe.

Minimum level

selection, with lubricant

below the minimum

and pump operating.

Minimum level incorrectly regulated.

The control panel lamp always remains on: check the

electric connection and replace the laser probe if

necessary.

9. MAINTENANCE PROCEDURES

The pump was designed and built in order to minimise maintenance requirements.

To simplify maintenance, it is recommended to install it in an easy to reach position.

•

Periodically check the pipe joints to detect any leaks. Furthermore, always keep the pump clean to be able to quickly detect

any leaks or defects.

•

Check if the loading filter is clean after every 2000 hours of operation.

The machine does not require any special equipment for any control and/or maintenance activity. It is recommended to use

tools and personal protective devices suitable for use (gloves) and that are in good condition according to current regulations to

prevent damage to people or machine parts.

ATTENTION

:

Make sure that the electric and hydraulic power supplies are disconnected before carrying out any

maintenance work.