HeatMax II Furnace Installation and Operation Manual

62

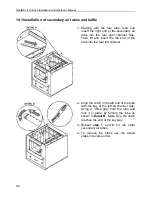

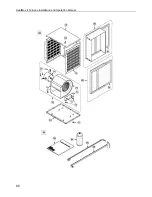

10.1 Installation of secondary air tubes and baffle

1- Starting with the rear tube, lean and

insert the right end of the secondary air

tube into the rear right channel hole.

Then lift and insert the left end of the

tube into the rear left channel.

2- Align the notch in the left end of the tube

with the key of the left air channel hole.

Using a “Wise grip” hold the tube and

lock it in place by turning the tube as

shown in Detail B. Make sure the notch

reaches the end of the key way.

3- Repeat step 1 and 2 for the other

secondary air tubes.

4- To remove the tubes use the above

steps in reverse order.

Summary of Contents for HEATMAX II DF01001

Page 30: ...HeatMax II Furnace Installation and Operation Manual 30 ...

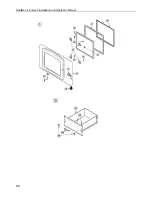

Page 64: ...HeatMax II Furnace Installation and Operation Manual 64 11 Exploded diagram and parts list ...

Page 65: ...HeatMax II Furnace Installation and Operation Manual 65 ...

Page 66: ...HeatMax II Furnace Installation and Operation Manual 66 ...

Page 67: ...HeatMax II Furnace Installation and Operation Manual 67 ...

Page 68: ...HeatMax II Furnace Installation and Operation Manual 68 ...

Page 74: ...HeatMax II Furnace Installation and Operation Manual 74 12 2 1 Technical data HeatMax II ...

Page 75: ...HeatMax II Furnace Installation and Operation Manual 75 ...