CON-2

XII.F.

(Continued)

On bellows valves, also install a clean

pipe plug in the bonnet vent connection,

until it is finger tight. The purpose of this

is to obtain the smallest possible leak

path. Remove this plug upon

completion of test.

Examine the following valve components

for leakage during back pressure testing:

a.

The nozzle/base joint.

b.

The adjusting ring pin seal.

c.

The base/bonnet joint.

d.

The bonnet/cap joint.

e.

If conventional valve, the “tight”

bonnet vent plug.

f.

The “loose” bonnet vent plug, if

bellows valve.

Leakage is best detected by application

of a liquid leak detector.

NOTE:

The use of soap, or household

detergent, as a leak detector is not

recommended, as it may bridge small

leaks.

Repair of leaking valve joints may be

attempted by tightening the leaking joint

while the valve is still on the stand. If this

does not stop the leak, tear down and

inspect the leaking joint(s); both the metal

surface(s) and gasket(s).

If the valve internals have been disturbed,

it is necessary to retest in accordance

with the instructions contained in this

manual. Otherwise, repeat the back

pressure tests, as outlined above.

5.

Blowdown Adjustment

Blowdown adjustments are made by

means of the adjusting ring on Type 1900

valves.

If longer or shorter blowdown is required,

it can be obtained as follows:

a.

To increase the blowdown (lower

reseating pressure), the adjusting ring

must be raised by moving the notches,

from left to right, past the ring pin

hole.

Page 38

b.

To decrease the blowdown (raise

reseating pressure), the adjusting ring

must be lowered by moving the

notches, from right to left, past the

ring pin hole.

NOTES:

•

Unless the test stand

capacity is equal to,

or greater than, that

of the valve, do not

attempt to set

blowdown. Simply

return the adjusting

ring to the recom-

mended position.

(Tables 12-14).

•

The valve will not

achieve rated re-

lieving capacity if the

adjusting ring is

positioned too low.

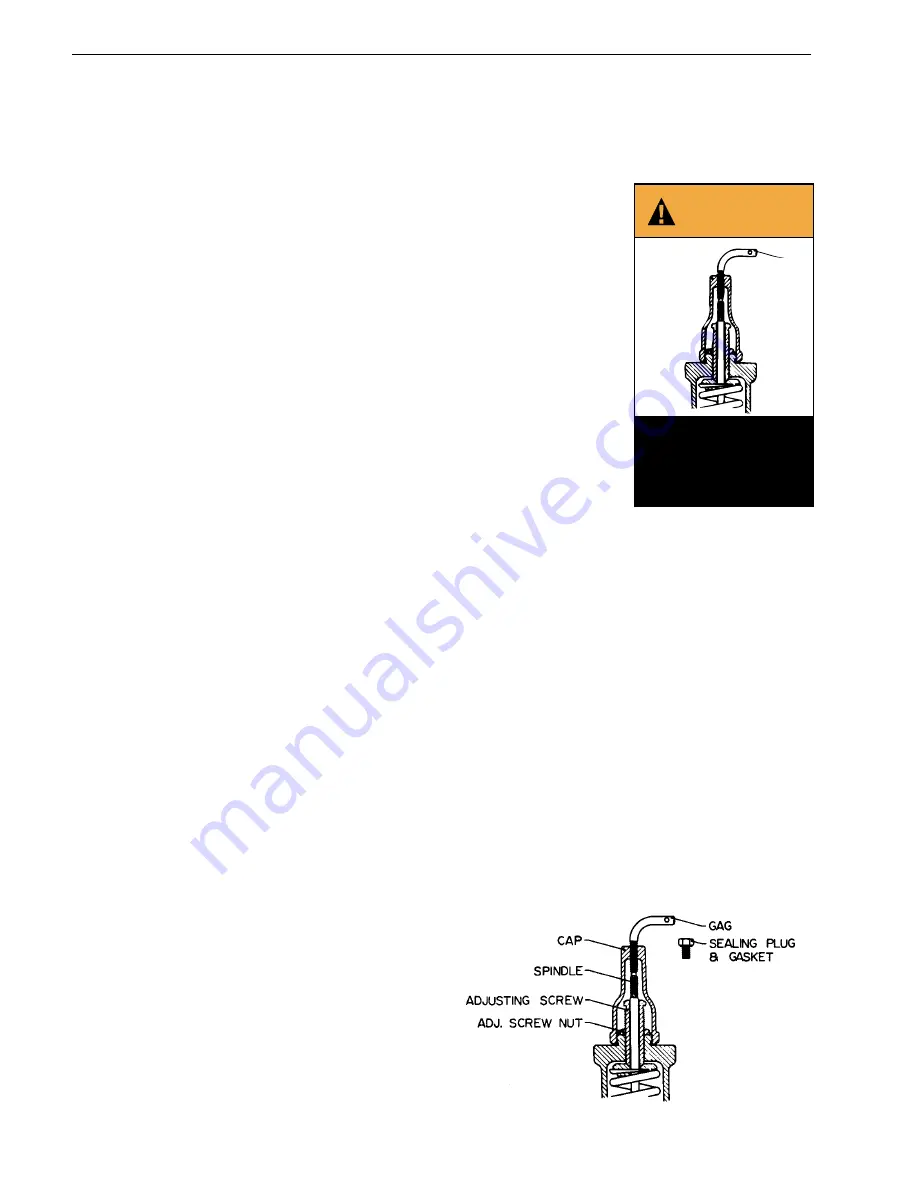

Gag safety valve during

ring adjustments to

avoid possible severe

personal injury or death.

y or death.

GAG

WARNING

FIGURE 37

XIII. Hydrostatic Testing

and Gagging

When hydrostatic tests are required after installation of

a safety relief valve, the safety relief valve should be

removed and replaced with a blind flange, if the

hydrostatic test pressure will not be greater than the

operating pressure of the equipment, a test gag may be

used. Very little force (i.e., fingertight pressure) on the

test gag is sufficient to hold hydrostatic pressures. Too

much force applied to the gag may bend the spindle

and damage the seat. After a hydrostatic test, the gag

must be removed and replaced by the sealing plug

furnished for this purpose. (Test gags for Consolidated

®

Safety Relief Valves can be furnished for all types of

caps and lifting gears.)