CON-2

X.H. (Continued)

2.

Machining Procedure: Metal to Metal Seat

See Figure 15, page 15.

a.

Take light cuts across the surface L at 5

°

,

until the damaged areas are removed.

(See Figure 15) Turn to the smoothest

possible finish.

b.

Cut back the outside surface at G, until

dimension N is obtained. The surface at

G is common to all nozzles except the

D-1. Omit this step on the D-1 orifice

nozzles.

c.

Machine bore diameter H, until

dimension E is obtained. Re-establish

angle P.

d.

The nozzle is now ready for lapping.

e.

When the minimum dimension D is

reached, the nozzle should be discarded.

3.

Machining Procedure: O-Ring Seat Seal

See Figure 15, page 15.

a.

Take light cuts across surface A (45

°

),

until the damaged areas are removed.

Turn to the smoothest possible finish.

b.

Cut back the outside surface at M, until

dimension J is obtained.

c.

Machine radius B.

d.

The nozzle is now ready for grinding.

e.

When the minimum dimension D is

reached, the nozzle should be discarded.

I.

Remachining the Disc Seat*

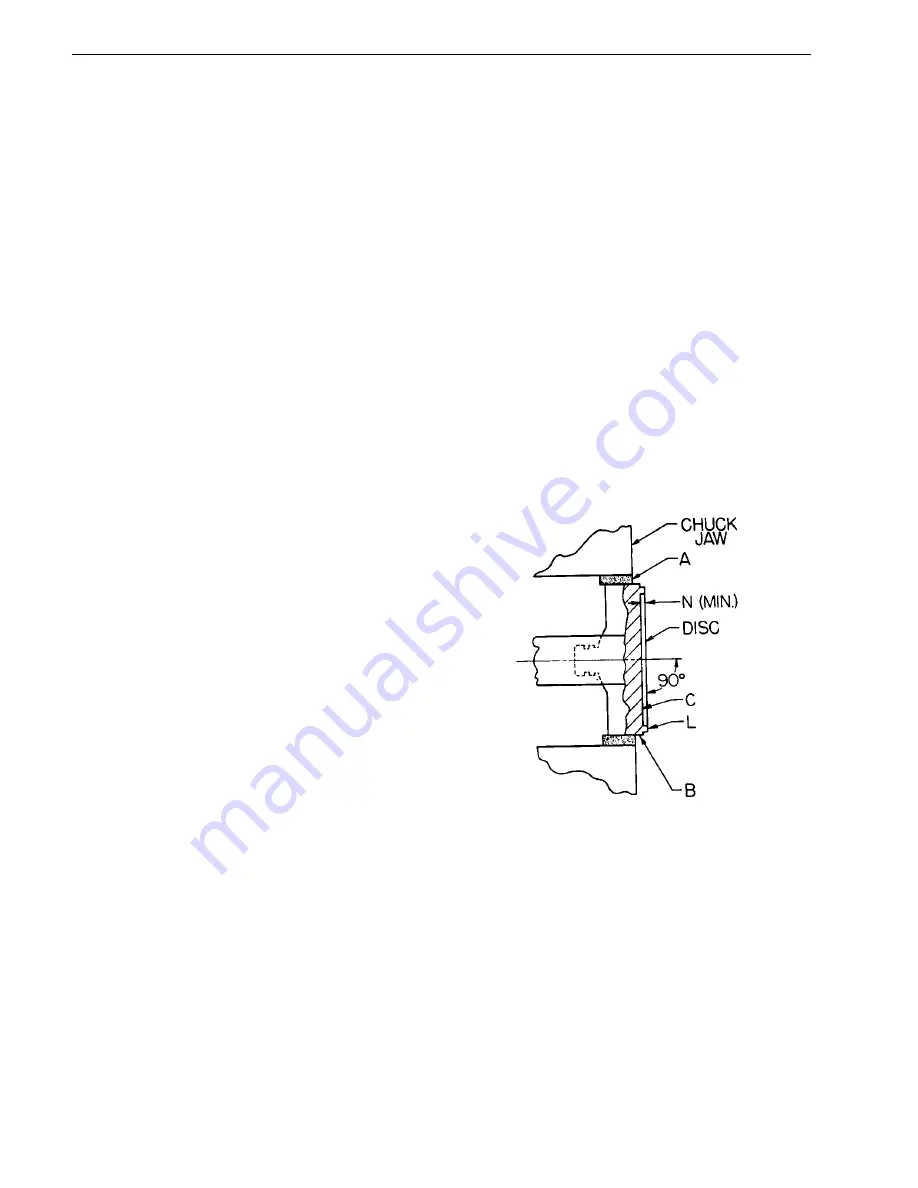

The standard disc seating surface (see Figure

30) can easily be machined as follows:

1.

Grip the disc in a four-jaw independent chuck

(or collet, if appropriate), using a piece of soft

material such as copper or fiber between the

jaws and the disc as shown at A.

2.

True up the disc so that the surface marked

B and C run true within .001" (0.025 mm),

TIR.

3.

Take light cuts across the seating surface L

until damaged areas are removed. Turn to

smoothest possible finish.

4.

The disc is now ready for lapping.

5.

When the minimum dimension N or T (see

Table 3) is reached the disc should be

discarded. Do not re-establish surface C.

*Thermodisc

®

and O-Ring discs are not to be machined.

FIGURE 30

Page 26