CON-2

Approximate Leakage

Maximum

Rate (Standard Cubic

Type of

Manufacturer's

(Bubbles per

Feet per 24 hour)

Valve

Orifice Size

Minute)

Maximum

Conventional F and smaller

40

0.60

G and larger

20

0.30

Balanced

F and smaller

50

0.60

Bellows

G and larger

30

0.45

Page 37

XII.

(Continued)

F. Seat Tightness Testing

1.

General Information

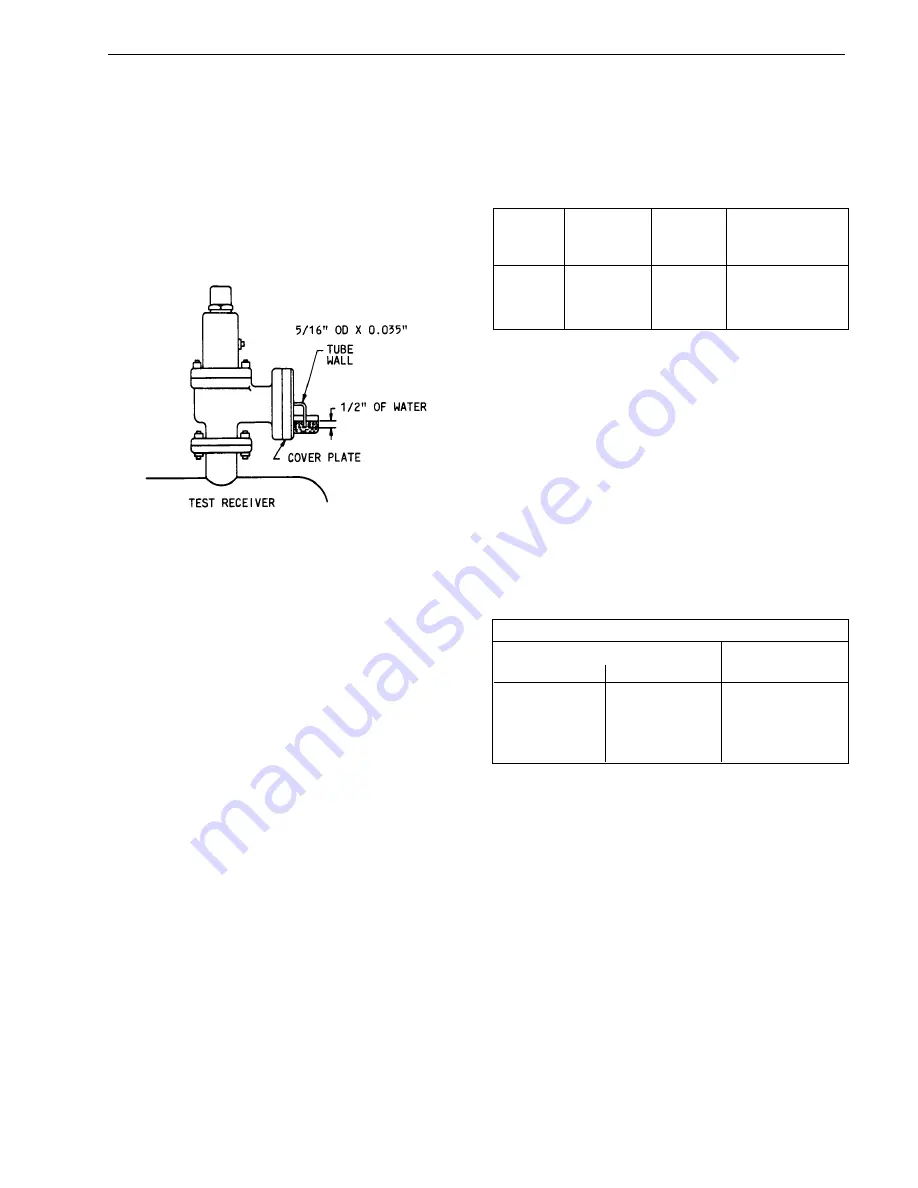

A typical test arrangement for determining seat

tightness for safety relief valves on air or gas

service (in accordance with ANSI B147.1/API

RP 527) is shown in Figure 36.

FIGURE 36

For metal to metal valves, designated for

gaseous service, the leakage rate (in

bubbles per minute) shall not exceed that

shown in Table 17.

TABLE 17

There shall be no visible leakage for

valves designated for steam service (and

tested on steam) or for liquid service (and

tested on water).

3.

Seat Tightness Testing for O-Ring Seat

Seal Valve

The “Tightness Standard’, for O-Ring seat

seal valves shall be no leakage at, or

below, the test pressures shown in Table

18, below.

4.

Recommended Back Pressure Testing

for Joint Leakage

After a given valve has been set for the

correct opening pressure, and if the valve

is to be used in a closed discharge system,

it should be back pressure tested. Testing

can be conducted by installing the cap,

with gasket, and applying air, or nitrogen,

to the base drain connection, or to the

valve outlet. All other openings must be

sealed.

Test pressure should be the greater of 30

psi (2 bar), or the actual valve back

pressure. Air, or nitrogen, pressure should

be held for 3 minutes, before applying

leak detector solution to all connections

(joints).

Set Pressure

Test Pressure

(psig)

(bar)

(% of Set Pressure)

5 to 30

.35 to 2.07

90

31 to 50

2.14 to 3.45

92

51 to 100

3.52 to 6.9

94

100 and above

6.9 and above

95

Seat Tightness Testing for “O” Ring Seat Seals

®

TABLE 18

Leakage measurement shall be made

with the use of a piece of 5/16 in. OD

tubing with 0.035 in. wall. The tube end

shall be cut square and smooth. It shall

also be perpendicular to, and 1/2 in. below,

the surface of the water.

2.

Seat Tightness Testing: Metal to Metal

Seats

With the valve mounted vertically (as

shown in Figure 39 above), the leakage

rate, in bubbles per minute, shall be

determined with pressure at the safety

relief valve inlet, which must be held at 90

percent of the set pressure immediately

after popping. For valves set at 50 psig or

below, the pressure shall be held at 5 psi

below set point. The test pressure shall

be applied for a minimum of 1 min. for

valves on inlet sizes through 2 inches; 2

min. for sizes 2-1/2, 3 and 4 inches; and

5 min. for sizes 6 and 8 inches.