6 |Dresser Natural Gas Solutions

6.1 Acceptable Lubricants

Standard lubricants and acceptable substitutions for

use in the actuator in Table 3.

Recommended

Manufacturer

AeroShell Grease 6

Shell Oil Products

Substitute

Manufacturer

Lubriplate MAG-1

Fiske

Mobilgrease 28

Mobil

Litholene HEP1

ARCO

Mobilux EP1

Mobil

Gulfcrown EP1

Gulf

7.0 Troubleshooting Guide

In the event of a problem with your Andco actuator, make

the following preliminary checks before calling the factory for

assistance.

1. The actuator’s rod will not extend or retract.

a. Check for a blown fuse or circuit breaker in the wiring.

b. Check for loose wiring.

c. Check if the motor has overheated and activated the

thermal switch.

d. Check that the limit switches are set correctly.

e. Check the binding in the load being actuated.

f. Check if a capacitor lead is open.

g. Check if the drive nut is damaged or worn, by

disconnecting the actuator from the load and pulling

or pushing on the extension rod.

8.0 Optional Equipment

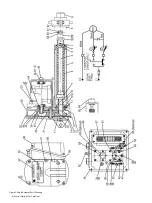

8.1 Gear Driven Potentiometer

This optional assembly is directly driven by the operation of

the actuator and gives the capability of providing a continuous,

linear output signal directly proportional to the actuator’s stroke.

The signal can be interfaced with automatic control equipment

to position or sense the actuator at any desired stroke between

fully extended and fully retracted. The potentiometer assembly

is mounted directly to and driven by the geared position limit

switch assembly. Characteristics of the potentiometer are 1000

ohm total resistance ±2.0% linearity, 1 watt at 40°C power

rating. Input gearing to the potentiometer is factory selected

to accommodate the full range of the actuator’s strokes and

the acme screw pitches. The potentiometer has been factory

adjusted so the 0 and 1000 ohm resistance points correspond,

respectively, to the fully extended and fully retracted rod

positions. Field adjustments may be made by loosening the jam

nut holding the potentiometer (64) to the mounting bracket

(65). Rotate potentiometer to the desired position and tighten

the jam nut. Potentiometer only to be connected to a class II

power source.

For units that utilize the last portion of the actuator stroke only;

the potentiometer gearing must be disconnected if the unit is to

be retracted beyond the “zero” point.

Table 3 - Standard and Substitute Lubricants

Stroke

(Inches)

Actuator Lubricant Amount

(Body Tube)

(Pounds)

6

.22

12

.36

18

.51

24

.66

30

.81

36

.96

Table 2 - Actuator lubricant amount per stroke length

6.0 Lubrication Instructions

Every Eagle linear actuator has been lubricated for life at the

factory and should not require further lubrication if operated

at published duty cycle, rated thrust and in appropriate

environmental conditions. However, if the unit is disassembled,

it should be cleaned and lubricated as given in step 4 of Section

6.0. The amount of lubricant in each actuator depends on the

stroke of the actuator as shown in Table 2.

2. The actuator only actuates in one direction.

a. Check that all wiring connections are secure.

b. Check that the position limit switches are

set correctly.

c. Check for an excessive external load on the

actuator in one direction.

3. The actuator is excessively noisy.

a. Check for a damaged bearing.

b. Check for a damaged gear (chipped tooth,

missing teeth, etc.)

c. Check for a damaged screw.

4. Actuator exhibits high motor current.

a. Check for low line voltage.

b. Check for external binding related to the load

being actuated.

c. Check for excessive external load being actuated.

d. Check for loss of lubricant.

e. Check the extension rod for excessive contaminates.

If you still have a specific problem with your Andco Eagle

Actuator after making all of the above checks, contact Dresser

NGS for further assistance.