4 |Dresser Natural Gas Solutions

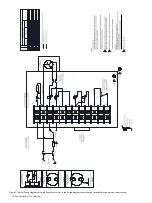

5.0 Electrical and Functional tests

Functional Test:

1. Unit ratings (voltage, speed, stroke, options, etc) are to be

confirmed with the Sales Order.

2. Wiring is to be confirmed through continuity tests refenced

from the assigned wiring diagram. Electrical connections

and components are to be secure.

3. Unit is to be run in both directions through the full rated

stroke. Unit should operate smoothly without unusual noise

or vibration.

4. Unit housing is to be visually inspected for mechanical

soundness and esthetics.

WARNING

MOVING PARTS

Internal moving parts. Pinch point

hazard. Keep hands clear during

operation.

WARNING

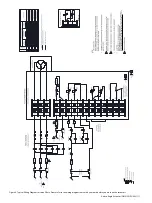

HAZARDOUS VOLTAGE

Disconnect all electrical power to the actuator prior to performing

any service or maintenance. Unit may have more than one live

circuit. Refer to wiring diagram supplied with unit.

CAUTION

BURN HAZARD

Possible hot surfaces. Keep hands clear of surface. Allow surface to

cool before performing any maintenance.

Disconnect all electrical power to the actuator prior to removing

the limit switch compartment cover and performing any setting

adjustments. Unit may have more than one live circuit. Refer to

wiring diagram supplied with unit.

WARNING

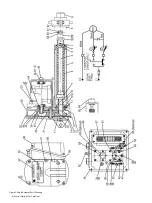

1. Remove the limit switch compartment cover (38) to gain

access to the position switch assembly.

2. Remove the motor pipe plug (46) for access to slot “A”

located in the end of motor shaft.

3. With a manual or power screw driver rotate the motor shaft

in a clockwise direction to extend or counterclockwise

direction to retract the extension rod.

4. To set the extend limit switch, turn the motor shaft in a

clockwise direction. Note the direction the slotted shaft (48)

is turning while extending extension rod to its

desired position.

5. Depress the position switch plunger (47) and turn the

slotted shaft (48) in the same direction it was turning as in

step 4 and continue to turn in this

direction until the cam (50) flat comes in contact with the

limit switch (52) lever.

6. Repeat steps 4 and 5 to set the retract limit switch utilizing

the slotted shaft (49), limit switch (53) and cam (51). Turn

the motor shaft in a counterclockwise direction.

7. Replace the motor pipe plug (46).

8. Replace the limit switch compartment cover (38).

9. Re-energize electrical power to the actuator.

If damaged, replace the complete geared position limit switch

assembly rather than attempting field repair.

NOTICE

En cas de dommage, remplacer l’assemblage complet de

l’interrupteur de fin de course du train d’engrenages plutôt que de

tenter une réparation sur place.

AVIS

Débranchez tous les câbles électriques de l'actionneur avant de retirer

le couvercle du compartiment de l'interrupteur de fin de course et de

procéder aux réglages. L'unité peut avoir plus d'un circuit sous tension.

Reportez-vous au schéma de câblage fourni avec l'appareil.

AVERTISSEMENT

ATTENTION

RISQUE DE BRÛLURE

La surface risque de devenir chaude. Éloignez vos mains de

la surface. Laissez refroidir la surface avant les travaux de

maintenance.

AVERTISSEMENT

PIÈCES MOBILES

Pièces mobiles internes.

Risque de point de pincement.

Tenez vos mains éloignées

pendant le fonctionnement.

AVERTISSEMENT

TENSION DANGEREUSE

Débranchez l'alimentation électrique de l'actionneur avant

d'effectuer une réparation ou un entretien. L'unité peut avoir plus

d'un circuit sous tension. Reportez-vous au schéma de câblage

fourni avec l'appareil.

4.0 Geared Position Limit Switch

Adjustment

The geared position limit switches have been preset at the

factory to trip and interrupt the electric control for the extend and

retract positions according to specified stroke. Final limit switch

adjustment must be done at installation. Set the extended and

retract limit switches to the positions required per the application,

the setting is to be done in accordance with the following

procedure.

CAUTION

BURN HAZARD

Possible hot surfaces. Keep hands clear of surface. Allow surface to

cool before performing any maintenance.

ATTENTION

RISQUE DE BRÛLURE

La surface risque de devenir chaude. Éloignez vos mains de

la surface. Laissez refroidir la surface avant les travaux de

maintenance.