Andco Eagle Actuator IOM NGS.IPG.0031| 5

5. Markings shall be visually inspected to be sure all warnings

and data plates are installed correctly.

6. Unit ratings (voltage, speed, stroke, options, etc) are to be

confirmed with the Sales Order.

7. Wiring is to be confirmed through continuity tests refenced

from the assigned wiring diagram. Electrical connections

and components are to be secure.

8. Unit is to be run in both directions through the full rated

stroke. Unit should operate smoothly without unusual

noise or vibration.

9. Unit housing is to be visually inspected for mechanical

soundness and esthetics.

10. Markings shall be visually inspected to be sure all warnings

and data plates are installed correctly.

Grounding Test:

Using a continuity tester, verify continuity between grounding

lugs and housing (bare metal).

Pressure Test:

1. Unit shall be pressurized to 3psi (.02 bar)

2. All surfaces and joints, including all gasket and o-ring sealed

surfaces shall be checked for leaks by applying a soap and

water solution and checking for signs of bubbles.

3. No bubbles should be observed.

4. Unit is to be dried after leak test is completed.

Electrical Withstand Test (Hi-Pot):

1. Test Voltage: 1200V

2. Withstand time: 1 second

The test equipment shall incorporate a transformer with an

essentially sinusoidal output, a means to indicate the applied

test potential, and an audible and/or visual indicator of dielectric

breakdown.

Method:

1. The test shall be conducted on products which are fully

assembled.

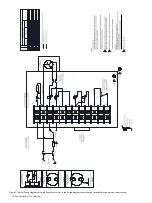

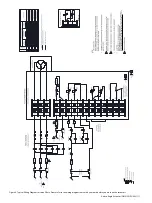

2. Refer to the assigned wiring diagram for specific test points.

3. The test voltage shall be applied between primary circuits

and accessible dead-metal parts. The test voltage may be

gradually increased to the specified value but must be

maintained at the specified value for one second.

4. If the rated output of the test equipment is 500VA or more,

the applied test potential may be indicated by either:

1 - A voltmeter in the primary circuit;

2 - A selector switch marked to indicate the test potential; or

3 - A marking in a readily visible location to indicate the

test potential for test equipment having a single test

potential output.

In cases 2 and 3, the test equipment shall include a lamp

or other visual means to indicate that the test potential is

present at the test equipment output.

5. All test equipment shall be maintained in current calibration.

6. The test equipment shall incorporate a voltmeter in the output

circuit to indicate directly the applied test potential if the rated

output of the test equipment is less than 500VA.

5.1 High Potential Test

1. Do not apply this test to units equipped with motor control

cards. Tests which involve putting electrical power to units

equipped with motor control cards are covered by a sepa-

rate procedure.

2. Select the voltage setting for the appropriate motor voltage

as indicated on nameplate. Set the selected test equipment

to the selected volts.

3. With the test equipment ground wire contacting the

gear case plate, contact each test point shown on wiring

diagram. The actuator shall be capable of withstanding for

one second per test point, without breakdown, the applied

voltage from Table 1.

Circuit

Voltage

Test

Duration/

Test Point

Test Voltage

(AC) setting

Max

Acceptable

Leakage

12 VDC

One Second

1000 Volts

10.33 mA

24 VDC

One Second

1000 Volts

10.33 mA

120 VAC 1PH One Second

1200 Volts

10.33 mA

220 VAC 1PH One Second

1200 Volts

10.33 mA

220 VAC 3PH One Second

1200 Volts

10.33 mA

460 VAC 3PH One Second

1200 Volts

10.33 mA

575 VAC 3PH One Second

1200 Volts

10.33 mA

Note: Motor power circuits are to be tested based on the motor

voltage (AC). Dielectric strength tests may be made by applying

a direct current (DC) voltage instead of an alternative current (AC)

voltage, provided that the voltage used is 1.414 times the values

specified above. See wiring diagram for test points.

5.2 Ground Continuity

1. Verify continuity between actuator ground lug and ground.

5.3 Functional Test

1. Electrically energize the actuator.

2. Drive the actuator over the full range of motion.

Table 1 - HIPOT Testing Specifications