9150-065-Y-12-20

24

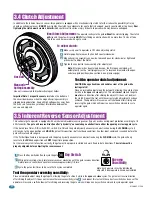

3.4 Clutch Adjustment

Test the operator clutch adjustment:

CAUTION: Keep pedestrians and vehicles clear of the gate while

testing clutch!

Place an immobile object along the gate path, allowing the gate to strike

it while in the

open

and

close

cycles. The clutch

must

slip and the gate

must

reverse direction after striking the object. If it does not, readjust

the clutch. Repeat this test until the correct clutch adjustment has been

achieved. The operator will assume a soft shutdown after striking and

reversing the gate which will require a key switch command to cycle

operator again.

1

2

3

4

In addition to the inherent reverse sensor, this operator is equipped with a mechanical slip clutch to further reduce the possibility of injury

should an entrapment occur.

DO NOT

over tighten the clutch to compensate for a gate that is damaged, poorly constructed or too heavy.

Over

tightening the clutch would create a hazard

which could result in serious injury or death to persons who may become entrapped.

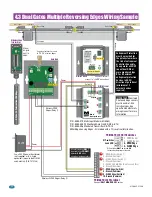

Hex Bolt

Magnetic

Spring Assembly

To adjust clutch:

Hex nut is connected to black plastic magnet holder.

Important Note:

2

magnetic sensors

located on the bottom of

the circuit board sense when the magnetic spring assembly is

slipping during operation. Keep all high voltage wires away from

the 2 sensors to avoid any electrical interference between the

sensors and magnets.

Note:

After power has been turned back on, the first open command will

automatically run the “multiple gate cycles” to locate and remember the open

and close gate positions (See section 3.3 on previous page).

Make sure power to operator is OFF when adjusting clutch.

Hold large pulley to loosen the hex bolt counter clockwise.

Magnetic spring assembly can now be loosened (counter clockwise) or tightened

(clockwise) to adjust the clutch.

Tighten the hex bolt to lock assembly after adjustment.

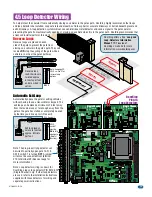

3.5 Inherent Reverse Sensor Adjustment

Test the operator reversing sensitivity:

Press the Key Switch button to cycle the gate.

While gate is cycling, slowly rotate reverse sensor clockwise until the gate reverses direction.

Rotate reverse sensor back counter-clockwise approximately 1/8 turn.

Cycle the gate a few times to be sure that it cycles completely.

Place an immobile object along the gate path, allowing the gate to strike it while in the

open

and

close

cycles. The gate must reverse direction

after striking the object. If it does not, increase the reverse sensitivity (step ) and repeat this test until the correct sensitivity has been set. The

operator will assume a soft shutdown after striking and reversing the gate which will require a key switch command to cycle operator again.

1

2

2

3

Min

Max

Sensitivity

Key Switch

Reverse

Sensitivity

Note: Each operator must be individually

adjusted if dual operators have been installed.

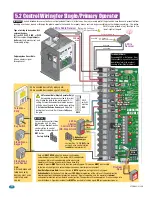

Ideal Clutch Adjustment:

The operator will cycle the gate

without

the clutch slipping. The clutch

will

slip and the gate will reverse

ONLY

after striking an obstruction with no more than 75 Lbs of force.

This force can be measured with a gate scale.

This vehicular gate operator is equipped with an inherent adjustable reversing sensor (Type A) used as entrapment protection according to UL

325 standards.

The gate will reverse direction after “physically” encountering an obstruction in either the opening or closing gate cycle

.

If the Auto-Close Timer (DIP-switch SW 1, switch 2) is ON and the gate physically encounters an obstruction during the

CLOSING

cycle, it

will reverse to the open position and

HOLD

the gate at this position (Soft shutdown condition). Another input command is needed before the

gate will reset and close again.

If the Partial Open Feature is being used and the gate physically encounters an obstruction during the

CLOSING

cycle, the gate will only

reverse to the

FULL

open position and

NOT

the partial open position.

For the reverse system to function correctly, the gate must be properly installed and work freely in both directions.

The clutch must be

properly adjusted before adjusting the reverse sensor.