INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

37

In the case of crane series CBE-MBE size V-Z integrate at the point 5

5.1

Insert into the central hole of the upper side pivots’ flange (

5

), the greaser (

10

) and introduce the

grease with the proper equipment.

fig. 52

Note: Check and grease every three months.

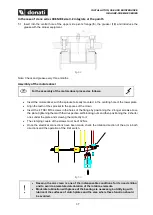

Assembly of the motoreducer

For the assembly of the motoreducer proceed as follows:

•

Insert the motoreducer, with the sprocket already mounted, in the centring hole of the lower plate.

•

Align the teeth of the sprocket to the spaces of the crown.

•

Insert the 4 TCEI M10 screws in the holes of the flange by positioning the 2 longer screws above

the plate, tightening them with their respective self-blocking nuts and then positioning the 2 shorter

ones under the plate and screwing them directly to it.

•

The clamping couple of the screws must be of 32 Nm.

•

Once the electrical connections have been made, check the rotation direction of the arm in both

directions and the operation of the limit switch

.

fig. 53

•

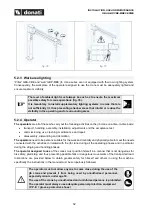

Keeping the arm clean is one of the indispensable conditions for its good sliding

and to avoid a premature deterioration of the rotation elements.

•

Moderate lubrication with grease of the bearings is necessary, but dirtying with

lubricant the surfaces of clutch plates and the area where these function should

be avoided.