INSTALLATION, USE AND MAINTENANCE

GBA-GBP-CBE-MBE SERIES

34

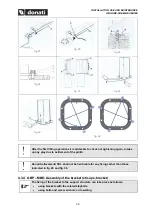

•

The fixing of the bracket using bolts and screw anchors or dowelling, requires a

scrupulous check of suitability in relation to the type of support.

•

Technical data, so that the user can scale the fixings to the right size are shown

in the table at paragraph 2.2.9

– “GBA/GBP and CBE/MBE: Fixing systems for jib

”).

•

The suitability checks of the support structure are the responsibility of the user

and must be carried out by expert technicians who evaluate the feasibility and take

on the related responsibilities.

Assembly of the brackets to the pillar or load-bearing wall:

1. Screw up the nuts

1

on the four staybolts

T

and insert the contrast panels

2

2. Assemble the two brackets, the front one

3

and the back one

4

, for the fixing of the upper part of the

bracket, in such a position to obtain the required height under the arm of the crane, inserting the safety

washers

5

and the cramping nuts

6

on the staybolts

T

3. Pretighten the nuts

6

to ensure good adherence to the pillar brackets (fig. 37).

fig. 35

fig. 36

fig. 37

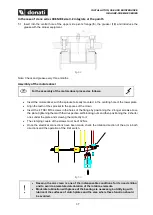

Assembly of the brackets:

1. Assemble on bracket

1

the other front bracket (fig. 38).

2. Lift the bracket to a height with suitable equipment, by putting it in the sling as shown and fix it to the

front bracket previously positioned on the pillar (fig. 39).

3. Assemble on the front bracket fixed on the bracket, the other back bracket (fig. 40). (Refer to the

preceding point “Assembly of the brackets” at positions

1

and

2

)

fig. 38

fig. 39

fig. 40