Downflo Oval, DFO 2-4 and 3-6

24

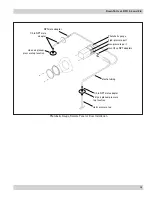

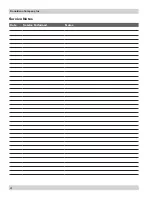

Magnehelic Gauge Installation

1/8-in NPT x 90°

male elbow

clean-air plenum pressure

tap location

1/8-in NPT adapter

1/8-in NPT adapter

plenum tap location

3/8-in flat washer

1/8-in NPT coupling

mounting bracket

#6-32 x 1/4-in mounting screws

support structure

mounting surface

Magnehelic gauge

high-pressure port

low-pressure port

two, 1/8-in NPT

adapters

plastic tubing

two, 1/8-in NPT pipe plugs

two, self-drilling screws

1/8-in NPT x 90° male elbow

dirty-air plenum pressure tap location

3/8-in flat washer

1/8-in NPT adapter

1/8-in NPT x 90° elbow

static pressure tee

Magnehelic

®

Gauge

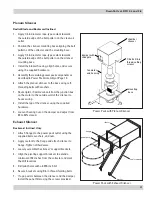

The Magnehelic is a differential pressure gauge used to

measure the pressure difference between the clean- and

dirty-air chambers and provides a visual display of filter

change requirements. The high-pressure tap is located in

the dirty-air plenum and the low-pressure tap is located

in the clean-air plenum.

1. Choose a convenient, accessible location on or near

the unit for mounting that provides the best visual

advantage.

2. Plug the pressure ports on the back of the gauge

using two 1/8-in NPT pipe plugs supplied. Install two

1/8-in NPT male adapters supplied with the gauge

into the high- and low-pressure ports on the side of

the gauge. Attach the mounting bracket using three

#6-32 x 1/4-in screws supplied.

3. Mount the gauge and bracket assembly to the

supporting structure using two self-drilling screws.

4. Thirty-five feet of plastic tubing is supplied and must

be cut in two sections. Connect one section of tubing

from the gauge’s high-pressure port to the pressure

fitting located in the dirty-air plenum. Connect

remaining tubing from the gauge’s low-pressure

port to the fitting in the clean-air plenum. Additional

tubing can be ordered from your representative.

5. Carefully remove the cloth protecting the filters.

Close access doors and tighten securely by hand.

6. Zero and maintain the gauge as directed in the

manufacturer’s Operating and Maintenance

Instructions provided.

Summary of Contents for DFO 2-4

Page 1: ...2...

Page 3: ......

Page 5: ......

Page 12: ......

Page 14: ......

Page 15: ......

Page 17: ...Downflo Oval DFO 2 4 and 3 6 14 This Page Intentionally Left Blank...

Page 19: ......

Page 21: ...Downflo Oval DFO 2 4 and 3 6 18 This Page Intentionally Left Blank...

Page 22: ......

Page 23: ......

Page 24: ......

Page 30: ......

Page 37: ......

Page 41: ...Downflo Oval DFO 2 4 and 3 6 38 Service Notes Date Service Performed Notes...

Page 42: ...39 Donaldson Company Inc Service Notes Date Service Performed Notes...

Page 43: ......