INSTALLATION

77091 Issue 2 November 2003

31

Beware of trailing cables. For example, the printer requires a power cable.

Therefore, ducting or some other form of cable management may be required.

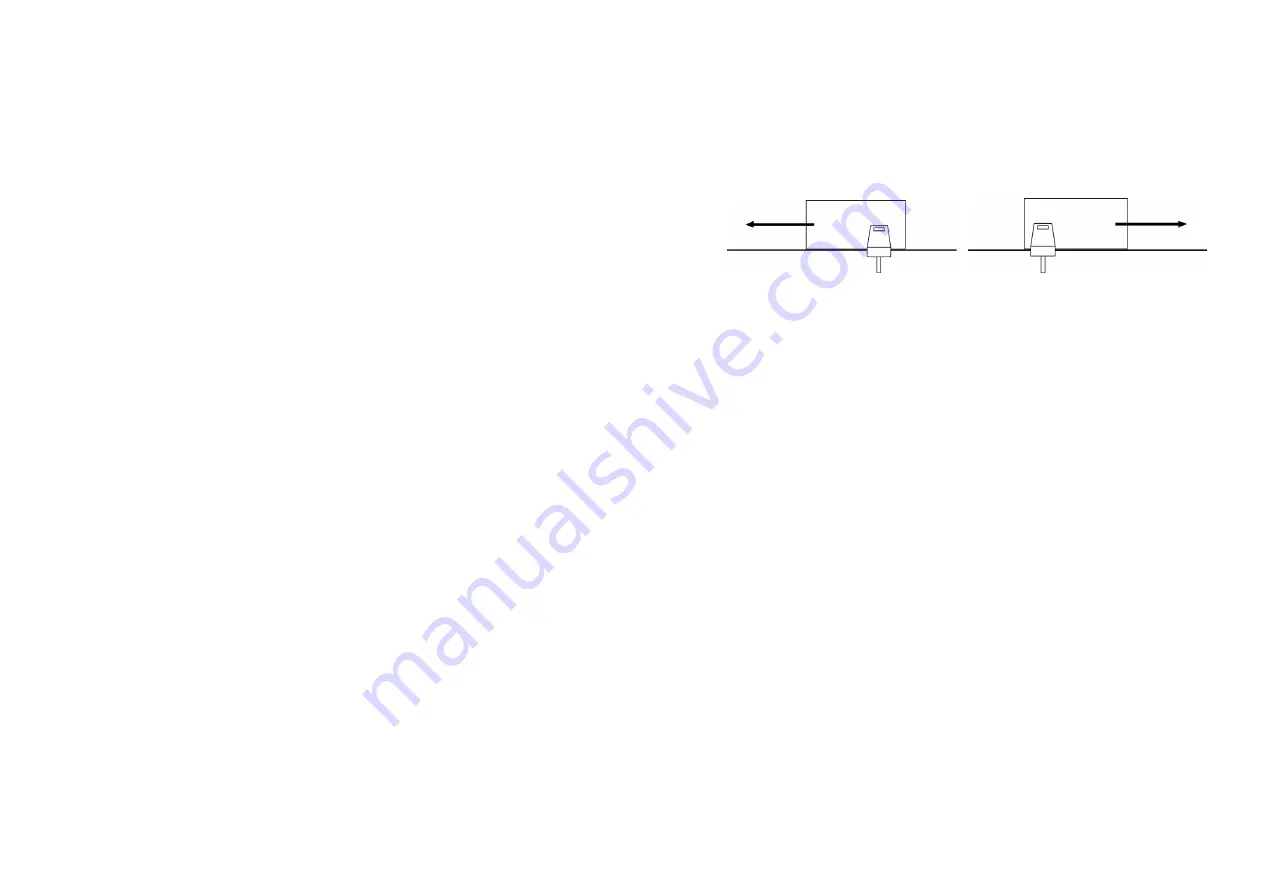

The printer is equally suited to right-to-left or left-to-right conveyor travel -

legibility in the latter case achieved simply by reversing the direction of print using

the operating software. Reversed printing also means that it is possible to print

simultaneously on both sides of items using more than one printer.

Each printer will need individual servicing, for example when replacing ink

bottles. A printer should not be placed in a location where it may be knocked or

jolted. The printer is also sensitive to vibration which may adversely affect print

quality.

For the best quality of print, select a power-driven section of conveyor for

mounting. Guide bars are essential to align the product to pass the print head only

just touching the front face.

Though items do not need to be equally spaced on the conveyor, there must be an

adequate gap - of at least 100mm - between them for the photocell to register the

arrival of each one. Items must not jam up on the conveyor; the photocell will not

recognise multiple products in a jam. This will result in missed products and

incorrect box counting.

Right to Left Conveyor Travel

Normal Printing

Left to Right Conveyor Travel

Reversed Printing

Summary of Contents for C Series

Page 1: ...C SERIES PRINTERS OPERATION AND MAINTENANCE MANUAL MODELS C7 C16 AND C34 ...

Page 6: ...6 77091 Issue 2 November 2003 ...

Page 16: ...SYSTEM OVERVIEW 16 77091 Issue 2 November 2003 C14 An Example of a Printed Message ...

Page 17: ...SYSTEM OVERVIEW 77091 Issue 2 November 2003 17 C34 ...

Page 18: ...SYSTEM OVERVIEW 18 77091 Issue 2 November 2003 C34 continued ...