2.

3.

4.

5.

6.

Check that the gas flame is lit and the gas mode in-

dicator lamp (C) is on.

Close the gas valve at the back of the refrigerator.

Wait for one minute. The check indicator lamp (E)

should now be lit and the gas mode indicator lamp

should be off.

Remove protection cover (see FIG. 1) and open the

gas valve. Test that no gas comes through the

burner jet. Use soupy water, rinse afterwords with

fresh water. Be careful not to damage the burner jet,

replace cover.

Make an ON-OFF operation with the main switch.

Normal gas operation should now return, operate

for at least five minutes.

VENTILATION REQUIREMENTS

When installing the refrigerator in the enclosure, all areas

at the front (sides, bottom and top) and within the recess

in which the refrigerator is installed must be sealed so

the resultant installation will isolate the appliance com-

bustion system from the vehicle interior.

Certified installation requires that one lower combustion

air intake and one upper exhaust vent be used. The

specified vent kit for this refrigerator must be installed as

directed by this manual without modification. Any devia-

tion or substitution other than the specified vent kit will

void this certification and the factory warranty of the

refrigerator.

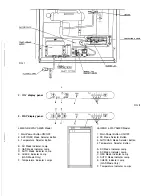

Venting must be in accordance with dimensions as

shown in FIG. 6. Any deviation will result in non-certifica-

tion.

Lower vent is to be utilized as a service entrance door.

Opening of lower vent must be flushed or below bottom

of refrigerator.

The condenser and absorber tubes (see FIG. 6) must

receive a continual supply of cooler air in order to main-

tain proper refrigerator cooling. A recommended 0”

clearance between the back of the refrigerator and the

coach wall helps the ventilation efficiency. The air pas-

sage (ventilation zone) from the lower vent door to the

refrigerator coils and from the coils up through the roof

vent must be unobstructed. If the air becomes trapped

by obstructions, the refrigerator will start to lose its ability

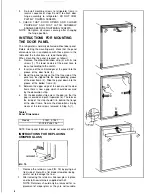

to cool. The proper ventilation zone, as shown in FIG. 8,

will create a chimney effect to incure adequate circula-

tion. It is important to block off the area above the

refrigerator cabinet from this ventilation zone (see FIG.

8). Also, air space at the sides of the refrigerator should

be minimized to prevent pockets of hot air from forming.

without adequate ventilation and/or with partial block-

age of flue exhaust, incomplete combustion (on GAS

operation) can cause carbon monoxide to form. Not only

does the refrigerator lose efficiency, but a poisonous gas

can result.

In the event of a prdpane leak, the properly installed

lower vent door will allow the propane to " Weep " to the

outside of the floor level, preventing large pockets of gas

from collecting.

Lower vent and roof jack must be A.G.A./CGA certified

for use with the refrigerator.

Roof jack opening must be centered directly above the

flue and condenser. (See FIG. 6 and 7.)

Table 2

Certified Vent System Kits

VENTILATION ZONE

VENTILATION ZONE

TOP VIEW

(LOOKING DOWN THROUGH OPENING)

FIG. 7

CUTOUT FOR ROOF JACK

F

L

UE

POCKETS SHOULD BE BAFFLED FOR PERFORMANCE

EFFICIENCY ALTHOUGH NOT REQUIRED FOR CERTIFICATION.

SEALED

SEAL STRIPS

SEAL STRIPS

6

Summary of Contents for Silhouette S1521

Page 14: ......