20

LUBRICATION

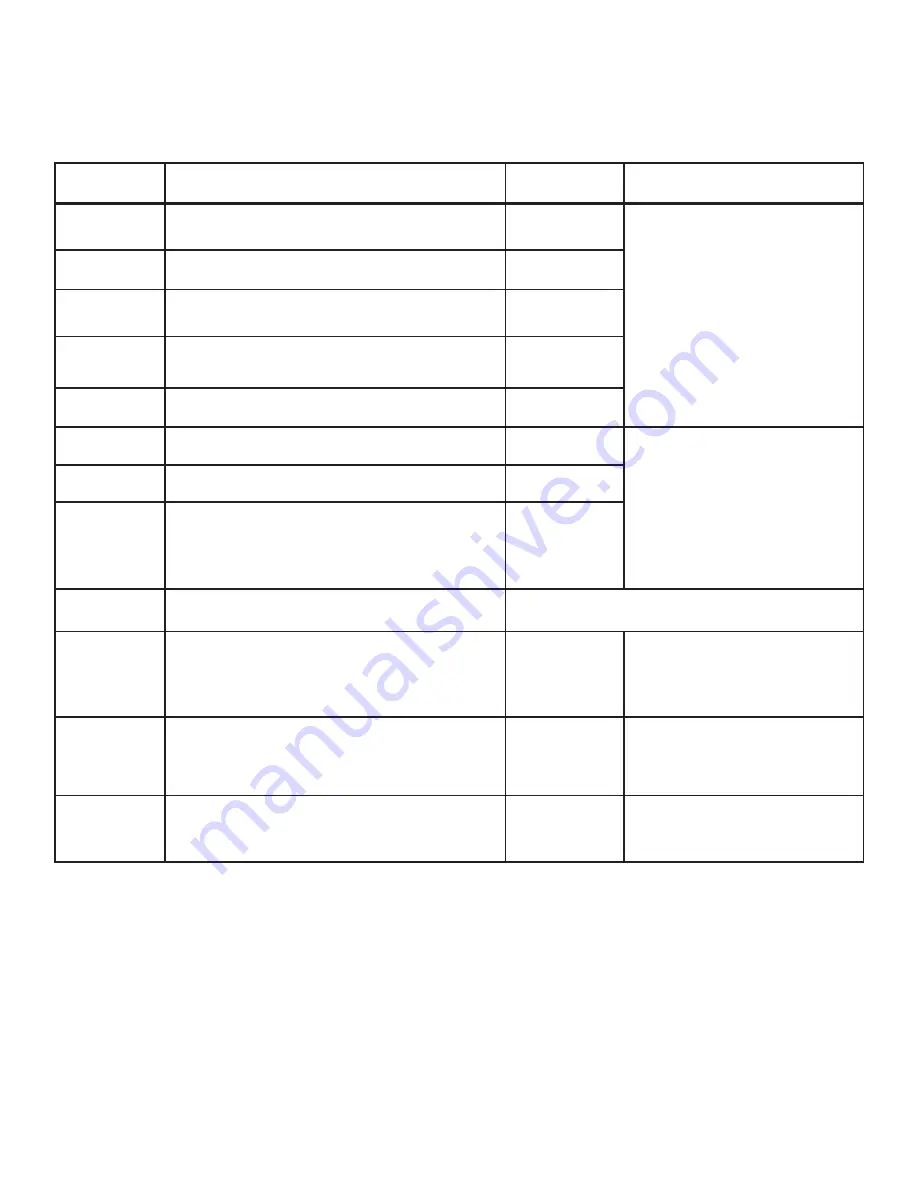

LUBRICATION CHART

LOCATION DESCRIPTION AND

SERVICE RECOMMENDATIONS

RECOMMENDED

LUBRICANT

LUBRICATION

INTERVAL*

LUBRICATION

POINT NO.

1

2

3

MONTHLY

WEEKLY

Insert Adjustment Screws.

Oil the threads.

INSERT CHANGE

Bandwheel Bearngs.

One (1) grease fitting each

bandwheel.

MONTHLY

MONTHLY

Head Carrage Lnear Bearng (Older machnes).

Four

(4) grease fittings.

Current machnes are sealed for lfe.

4

5

Head Pvot Pllow Blocks.

Two (2) grease fittings.

MONTHLY

6

Post.

Clean and apply oil.

7

MONTHLY

Mscellaneous: Vse Sldes, Hnges, Pvot Ponts,

Component Parts, Unpanted Surfaces, etc.

To ensure

function and maintain appearance while reducing wear,

corrosion, rust, etc. Apply when and where needed in

amounts required.

8

AS REQUIRED

High quality, rust and oxidation-inhibited,

medium hydraulic and general purpose

industrial oil.

ISO-VG Grade 68 (Formerly ASTM Grade

No. 315).

Union 76, UNAX RX 68, or equivalent.

Lubricate per manufacturer's recommendations.

9

Electrc/Hydraulc Motors.

Hydraulic Pump, Coolant,

Drive and Optional Chip Conveyor.

10

11

* Lubrcaton ntervals are based on a 8-hour day, 40-hour week.

Lubrcate more often wth heaver use.

Band Tenson Slde.

Clean and apply grease.

Vse Movable Jaw Sldes/Gbs.

Four (4) grease fittings.

1 for each gib. Add two (2) for

Optonal Outboard Vse

.

Premium quality, multi-purpose lithium-

base, EP (extreme pressure) grease.

NLGI No. 2.

Union 76, UNOBA EP 2, or equivalent.

12

Coolant Reservor (Drp Pan).

20 gallon (75.7 liter) capacity.

Chp Conveyor (Optonal).

50 gallon (189.2 liter) capacity.

Drain, clean and refill whenever coolant becomes

undesireable for further use. Clean the mesh strainer at the

same time.

Premium quality, saw band coolant and

lubricant.

DoALL cutting fluids and/or oils -

(Power-Cut).

CHECK DAILY/

AS REQUIRED

CHECK DAILY/

AS REQUIRED

Hydraulc Reservor.

20 gallon (75.7 liter) capacity.

Check oil level daily and keep the reservoir full. Drain,

change the filter element and refill after the 1st month;

every six (6) months thereafter.

Band Mst Lubrcator (Optonal).

Keep reservoir filled

and hoses clear.

Contact your DoALL sales representative

for the best oils and/or fluids for your

application.

DoALL cutting fluids and/or oils.

CHECK DAILY/

AS REQUIRED

Multi-purpose automatic transmission

fluid.

General Motors Dexron III, or equivalent.

Summary of Contents for TF-2025M

Page 1: ...TF 2025M Serial No 543 99101 to Band Sawing Machine Instruction Manual...

Page 5: ...MACHINE DIMENSIONS INCHES 03 MILLIMETERS 1 mm FLOOR PLAN...

Page 6: ...FRONT VIEW MACHINE DIMENSIONS Continued INCHES 03 MILLIMETERS 1 mm...

Page 7: ...MACHINE DIMENSIONS Continued SIDE VIEW INCHES 03 MILLIMETERS 1 mm...

Page 8: ...MACHINE FEATURES SIDE VIEW FRONT VIEW...

Page 9: ...MACHINE FEATURES Continued HEAD ASSEMBLY...

Page 10: ...MACHINE FEATURES Continued PROXIMITY LIMIT SWITCH LOCATIONS REAR VIEW HEAD TOP VIEW...