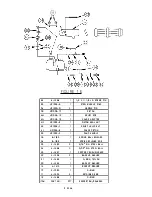

TROU B LES HOOTI NG, DIAGNOS IS AN D REM ED I ES

I

TROUBLE

1 . Tool fails

to

retra ct

pro perly.

2. Tool fails to build

up p ressure.

CAUS E OF TRO U B LE

1 . Excess hydrau lic oi l (oil

added with nibs not fu l ly

retracted).

2. Ram piston binding .

3. Spring pin 25 not flush with

swivel

1 4

surfa ce.

4. B roke n sp ring reta i ner

stud 9.

5. B roke n ra m return s pring 29 .

6. Tool head slide 4 a nd

housin g bindin g due to

accu mu lation of inhibitor

or dirt in hea d .

1 . Rel ease rod ha nd le p i n 27

m isadjusted .

2. 0- ring sticking .

3. Relief va Ive rod 48

h ol ding bal

I

va

Ive

open.

2 B O F 2S

REPAI R INSTR UCTIONS

I

1 . Fol low instructions of

ADDITION OF HYDRAULIC 01 L.

2. Fol low recomme n ded proced ures

in REMOVAL OF RAM LIP SEAL

steps 1 th rough 5.

3. Fol low recomme n ded proced ures

in TOOL H EAD DISASSEM BLY

a nd TOOL H EAD ASSEMBLY.

4. Fol low recomm e n ded proced ures

in

REMOVAL OF RAM UP SEAL

steps 1 th rough 5, a n d REMOVAL

OF RAM R ETU RN S PRI NG

Remove a nd repl ace the spring

reta i ner stud 9 .

5 . Fol low recomm e n ded proced ures

in REMOVAL OF RAM LIP SEAL

sleps 1 th rough 5, a n d

a nd R EMOVAL O F RAM RETURN

S P R I NG. Remove an d replace

the ra m return spri ng 29 .

6. Fol low recomm e n ded proced ures

in CLEANI NG AND LU BRICATING

TOOL HEAD.

1 . Fol low reco m mended proced ures

in ADJUSTM ENT OF R ELEASE

ROD P IN .

2 . Rotate man ua l advance handle

to ful ly extend indenters. Retract

indenters ful ly an d pu mp u nit.

3. Fol low recom mended proced u res

in REMOVAL OF RELIEF RO D

SEALS a nd I NS PECTION O F RELI EF

VALVE BALL.

Summary of Contents for HC134

Page 26: ...PORT ON SEE NOTE p SIDE E 1 6...