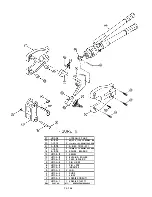

REMOVAL OF RAM LI P SEAL: (SEE FIG URE 7)

CAUTION: REMOVAL OF RAM LIP SEAL SHOULD NOT BE ROUTINELY U NDERTAKEN.

THIS SEAL SHOULD BE REMOVED ONLY AS A LAST RESORT. WHEN

HANDLING THIS S EAL, PARTICULAR CARE SHOULD BE TAKEN TO PROTECT

THE SEALING SURFACE AND NOT TO DISTORT THE SPRING ENERGIZER

DURING THE REMOVAL OR INSTALLATION PROCESS .

1. Fol low steps 1 th rough 6 of TOOL HEAD DISASSEMBLY.

2. Pu mp the tool handle several strokes to expose screw 3 located in ram 51

(see Figure 7). Fully remove scre w 3 and withdraw swivel 14 and slide 4

( see Figure 5).

CAUTION: AFTER REMOVING SLIDE ASSEMBLY, FULLY RETRACT RAM 51 (SEE FIGURE 7).

3. Using a hex wrench, fully remove screw 2 located in head adaptor 52 and

unscrew head adaptor.

4.

Place pump assembly in a pan and rem ove screw 4 and crush washer 1 9.

5. Grasp ram 51 and slowly pull to remove ram and seal assembly.

6. Remove spent seal 1 B, being careful not to damage any part of the ram's sealing

surface.

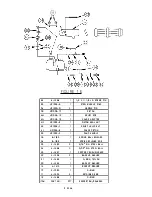

SEAL LI P ------....._

�

RETAINING LIP

_/'

RAM -

FI G U R E 1 1

INSTALLATION OF RAM LIP SEAL:

1. Follow steps 1 through 6 of REMOVAL OF RAM LIP SEAL.

2. Apply a small amo unt of g rease to the interior (1.D.) section of the seal 1 B

(see Figure 11 ). Slide the seal over the retaining lip of ram with the lip end

of the seal away from th e ram (see Figure 1 1 ).

3. Place the pum p assem bly in a vertical position in a soft jaw equipped vise.

4. Fill the ram cylinder approximately half full using the appropriate hydraulic

oil for the season.

5. Apply a small amount of g rease to the lip sections (0.0 . ) of the seal.

Carefully insert the ram into the cylinder (being careful not to damage the lip

surfaces of the seal 1 8 (see Fi g u re 1 1 ).

lli2I8 Cover the top of the ram with a clean cloth as some oil may be forced

out of the hole when pushing the ram to the bottom of the cylinder.

6. Reas semble by reversing the order of operations d escri bed in steps 1 through 4

of REMOVAL OF RAM LIP SEAL.

1 3 OF 28

Summary of Contents for HC134

Page 26: ...PORT ON SEE NOTE p SIDE E 1 6...