HF225 manual hydraulic butt welder

Simply Better.

Simply Better.

Simply Better.

Simply Better.

FUSIONMASTER®

and

DIXON

®

are registered trademarks of Dixon Industries Pty. Ltd.

©August 2002

Revised August 2013

Page 14

7.

Butt Welding Guidelines

It is recommended that the following guidelines be downloaded from Plastics Industry Pipe

Association of Australia Ltd web site (www.pipa.com.au)

1.

POP003 Butt Fusion Jointing of PE Pipes and Fittings - Recommended Parameters.

2.

TP003 Specifying Butt Welding of Polyethylene Pipe Systems.

FUSIONMASTER®

welders are designed for the “single pressure – low pressure” fusion

method described in POP003.

The welding tables appended to the HF225 operating manual are based on POP003-SP-LP.

Operators should take care to determine the compatibility of materials for butt welding and only

attempt to weld pipes and fittings made of the same polymer, eg PE to PE, PP to PP, PVDF to

PVDF, etc.

The joint area must always be protected from adverse weather conditions, eg strong winds,

excessive cold or heat, or rain, which could lead to the pipe wall developing non-uniformly

heated zones and consequent failure issues.

The weld zone should be free of bending stress, free of notches or similar damage, and be free of

contamination.

8.

Weld failure trouble shooting

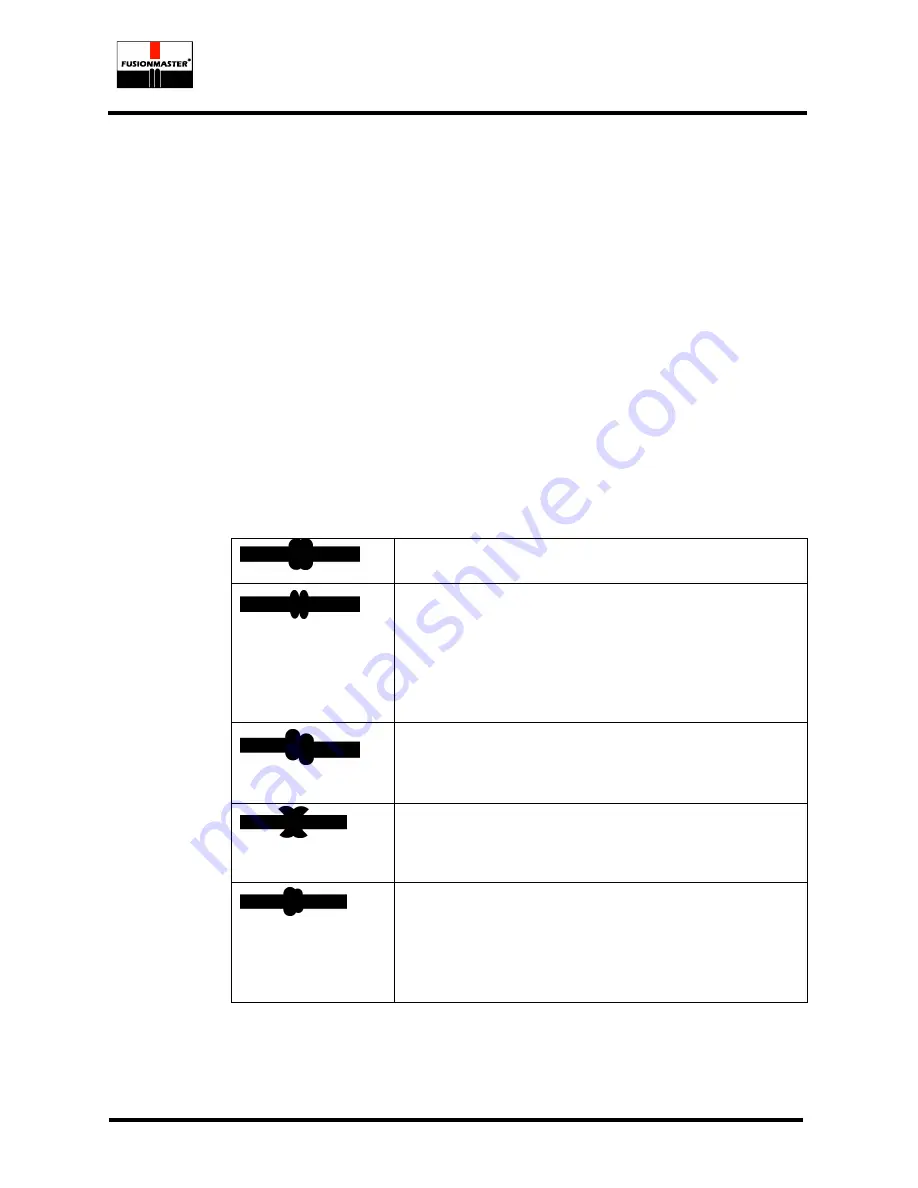

(Bead shapes are exaggerated for effect.)

Uniform bead correct welding.

NB the external bead is always more uniform than the internal bead.

Crack down centre of bead.

"Cold weld" signified by clean break through the middle of the weld

with a smooth appearance.

Could be due to insufficient heat soak time or temperature, or

changeover time too long, or excessive soak pressure, or insufficient

fusion pressure, or no allowance for drag pressure, or drag pressure

too great eg due to pulling pipe up a gradient.

Misalignment - maximum allowable 10% of wall thickness.

Care should also be taken to ensure pipes or fittings being joined

have the same diameter and wall thickness or the probability of weld

failure is significantly increased.

Insufficient bead roll over.

Could be due to insufficient heat soak time or temperature, or

changeover time too long, or insufficient fusion pressure, or no

allowance for drag pressure,

Unequal bead size.

Look for temperature gradients e.g. pipe surface in the hot sun vs

pipe in the shade, or heater plate hot spots.

Look for unequal application of pressure.

If unequal uniformly around the whole circumference, look for

physical difference in materials being joined eg melt flow index.