5.3 Routine Maintenance Schedule

• The filter frame must be replaced

so that the cage side is facing

upwards to prevent the media

from being sucked out of the frame

• Inspect the HEPA after filters

and replace if the filters are

saturated

3. Clean the inside of the unit completely from top to bottom, using

wire brush or scraper and a pressure washer to remove all

accumulated sludge and debris

• Remove the inlet duct to clean the inside of the back of the

collector and inspect the inlet ductwork for dust accumulation

4. Drain the dirty water using the optional WV-55 sludge-vacuum to

separate the metal fines from the water, remove sludge on the

bottom of the tank and skim the residual material floating on the

water surface

5. Open the water level control box to inspect

the level probes or ultrasonic sensor and

remove all accumulated particulate

1. Open the knobs or latches on the two

front panels of the wet dust collector

2. Inspect the mist eliminator filters inside the unit for holes or dust

accumulation, replace the media if torn or dirty

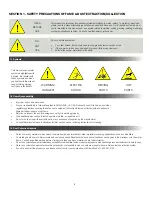

•

All debris must be

stored in a ventilated

metal drum to prevent

hydrogen gas buildup

• If the collector has the

optional strainer system,

remove the basket and

dump the accumulated

dust, clean out the

basket and replace it.

• Dust needs to be

disposed of according

to local regulation

6. If the level probe is loose, tighten the

terminal screw and ensure the probes are at

the right level and touching each other.

Ensure the probe gasket is cleaned of all

residue

• If the level probes require maintenance

use an abrasive sponge to remove all

accumulated particulate

7. Ensure the passage from the probe housing

to the water basin is free and clear of

debris

8. Once the entire machine has been cleaned

out, re-install the front doors, mist filters,

and probe box assembly

13

Whenever several inches of dust buildup inside the wet collector water tank, it is necessary to remove the material as soon as possible. Depending on

application dust loading, The Wet Collector may needs to be maintained daily.

Cleaning Instructions:

Summary of Contents for TYPHOON WX Series

Page 19: ...19 NOTES...