7

be placed on the casefeed post with the

Dillon logo and the on/off switch facing

you.

The casefeed tube (#20533*) should

now be inserted into the casefeed

adapter (#13654*)

Fig. 7

Note that the

tube is marked “up” on one end. Press

this end into the tube clip (#13859) at-

tached to the casefeeder motor hous-

ing

Fig. 8

. This assembly is now

complete.

Step 3: Installing the Powder Measure

Remove the blue cap from the powder

die (#20320) and loosely clamp the pow-

der measure in position.

Fig. 9

Install the

powder measure return rod (#13960)

through the 3/8” eyebolt (#13089)

mounted on the left rear of the main

frame.

Fig. 10

Now attach the rod to the

powder measure bellcrank using the clip.

Fig. 10

Install the spring (#14033) and

wing nut (#13799) on the rod and screw

the wing nut up until you feel light ten-

sion on the spring. Tighten the powder

measure clamp screws (#14037).

Step 4: Installing the Spent Primer Cup

and Bullet Bin

Install the spent primer cup (#16699)

on the right side as shown on the

schematic on page 27.

Fig. 11

Hook the bullet bin (#13756) and the

collection bin (#13484) on to their re-

spective brackets.

Fig. 12

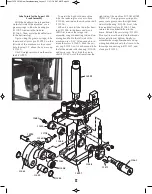

Fig. 6 - Shown is the proper position of the

power cable (13539), clamp (13495), and

bin support bracket (10991).

Fig. 7 - The proper location and positioning

of the casefeed tube and adapter is as shown

above.

Fig. 8 - The end of the casefeed tube marked

“up” snaps into the clip at the base of the

casefeeder motor housing.

Fig. 9 - A slight gap allows the powder die to

be adjusted without removing the powder

measure.

Fig. 10 - Note how the spring above the

wing nut is slightly compressed.

Fig. 11 - See the schematic on page 27 for

more details.

Fig. 12 - Shown is the proper location of

the cartridge collection bin. Note: the bul-

let bin is replaced by the optional bullet

tray in this photo.

Super 1050 2018 New Casefeeder.qxp_Layout 1 1/31/18 6:47 AM Page 7