OPERATOR’S MANUAL

PM300E and PM332E Planter Monitors

11001-1423-200710

INSTALLATION / 9

INSTALLATION

The monitor is tested and inspected before shipping to ensure the unit is

fully operational and meets measurement specifications. Inspect for

damage that may have occurred during transit. Save all packing materials

until the inspection is complete. If damage is found, immediately file a claim

with the carrier and notify your DICKEY-john Sales Representative.

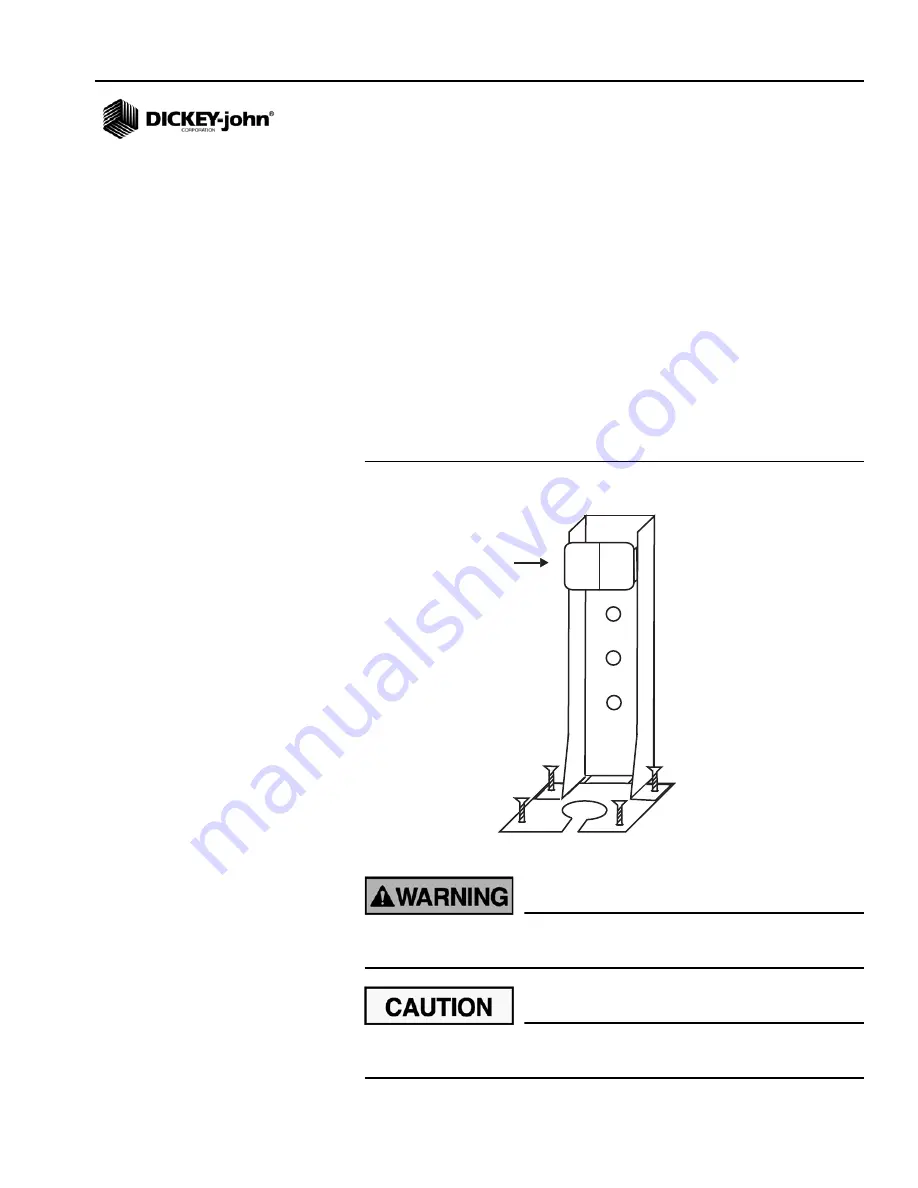

STANDARD MOUNTING BRACKET

NOTE:

When mounted to a vertical

surface, a tie-wrap can be used

to secure the cables to the

bottom of the bracket.

Install the mounting bracket at the desired location using locally acquired

hardware. Install the console to the bracket by aligning the console mating

grooves with the bracket and sliding the console onto the bracket until the

snap engages.

Figure 3

Standard Mounting Bracket

The console must not obstruct the view of the operator or interfere

with the operation of the tractor.

To prevent damage to the console, be sure the snap fully engages

during installation.

Slide console

until snap

engages

Mount on vehicle

with locally acquired

hardware

Summary of Contents for PM300E

Page 4: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 2 SAFETY NOTICES...

Page 8: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 6 INTRODUCTION...

Page 10: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 8 MAJOR FEATURES...

Page 14: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 12 INSTALLATION...

Page 30: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 28 AUXILIARY MODES...

Page 46: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 44 TROUBLESHOOTING...

Page 48: ...OPERATOR S MANUAL PM300E and PM332E Planter Monitors 11001 1423 200710 46 CONNECTOR PINOUTS...