ENGLISH

59

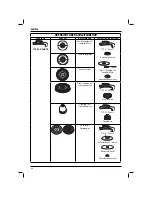

Fitting and Removing a

Backing Pad/Sanding Sheet

(fi g. 1, 8)

1. Place the tool on a table, guard up.

2. Remove the backing flange (g).

3. Place the rubber backing pad correctly onto the

spindle (d).

4. Place the sanding sheet on the rubber backing

pad.

5. Screw the threaded clamp nut (h) onto the

spindle. The ring on the threaded clamp nut (h)

must face towards the rubber backing pad.

6. Press the spindle lock button (c) and rotate the

spindle (d) until it locks in position.

7. Tighten the threaded clamp nut (h) with the two-

pin spanner.

8. Release the spindle lock

9. To remove the rubber backing pad, loosen the

threaded clamp nut (h) wih the two-pin spanner.

Prior to Operation

• Install the guard and appropriate disc or wheel.

Do not use excessively worn discs or wheels.

• Do not use a damaged accessory. Before each

use inspect the accessory such as abrasive

wheels for chips and cracks, backing pad for

cracks, tear or excess wear, wire brush for loose

or cracked wires. If power tool or accessory

is dropped, inspect for damage or install an

undamaged accessory. After inspecting and

installing an accessory, position yourself and

bystanders away from the plane of the rotating

accessory and run the power tool at maximum

no-load speed for one minute. Damaged

accessories will normally break apart during this

test time.

• Be sure the inner and outer flange are mounted

correctly. Follow the instructions given in the

Grinding and Cutting Accessory Chart

.

• Make sure the disc or wheel rotates in the

direction of the arrows on the accessory and the

tool.

OPERATION

Instructions for Use

WARNING:

Always observe the safety

instructions and applicable regulations.

WARNING: To reduce the risk

of serious personal injury, turn

tool off and disconnect tool from

power source before making any

adjustments or removing/installing

attachments or accessories.

WARNING:

•

Ensure all materials to be ground or

cut are secured in place.

•

Use clamps or a vice to hold

and support the workpiece to a

stable platform. It is important to

clamp and support the workpiece

securely to prevent the movement

of the workpiece and loss of control.

Movement of the workpiece or loss

of control may create a hazard and

cause personal injury.

•

Secure the workpiece. A workpiece

clamped with clamping devices or in

a vice is held more secure than by

hand.

•

Support panels or any oversized

workpiece to minimize the risk of

wheel pinching and kickback. Large

workpieces tend to sag under their

own weight. Supports must be

placed under the workpiece near the

line of cut and near the edge of the

workpiece on both sides of the wheel.

•

The gear case becomes very hot

during use.

•

Always wear regular working gloves

while operating this tool.

•

Apply only a gentle pressure to the

tool. Do not exert side pressure on the

disc.

•

Avoid overloading. Should the tool

become hot, let it run a few minutes

under no load condition to cool the

accessory. Do not touch accessories

before they have cooled. The discs

become very hot during use.

•

Do not use separate reducing

bushings or adapters to adapt large

hole abrasive wheels.

•

Never use the tool without the guard

in place.

•

The tool is not designed to be used

with a grinding cup.

•

Do not use the power tool with a cut-

off stand.