7

English

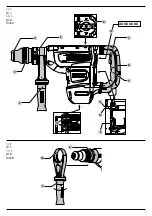

Side Handle (Fig. A, B)

WARNING:

To reduce the risk of personal injury,

ALWAYS

operate the tool with the side handle properly installed.

Failure to do so may result in the side handle slipping

during tool operation and subsequent loss of control. Hold

tool with both hands to maximize control.

The side handle 2 clamps to the front of the gear case and may

be rotated 360˚ to permit right- or left-hand use.

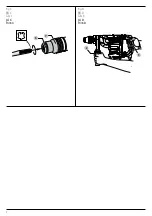

Mounting the Straight Side Handle

(Fig. B)

1. Widen the ring opening of the side handle

2

by rotating it

anti-clockwise.

2. Slide the assembly onto the nose of the tool, through the

steel ring

14

and onto the collar

3

, past the chisel holder

and sleeve.

3. Rotate the side handle assembly to the desired position. For

hammerdrilling horizontally with a heavy drill bit, place the

side handle assembly at an angle of approximately 20° to

the tool for optimum control.

4. Lock the side handle mounting assembly in place by

securely tightening the handle

2

rotating it clockwise so

that the assembly will not rotate.

Bit and Bit Holder

WARNING:

Burn Hazard.

ALWAYS

wear gloves when

changing bits. Accessible metal parts on the tool and bits

may get extremely hot during operation. Small bits of

broken material may damage bare hands.

The hammerdrill can be fitted with different bits depending on

the desired application.

Use sharp drill bits only.

Inserting and Removing SDS MAX

Accessories (Fig. C)

This machine uses SDS MAX bits and chisels (refer to the inset in

Figure C for a cross-section of an SDS MAX bit shank).

1. Clean the bit shank.

2. Pull back the locking sleeve

7

and insert the bit shank.

3. Turn the bit slightly until the sleeve snaps into position.

4. Pull on the bit to check if it is properly locked. The

hammering function requires the bit to be able to move

axially several centimetres when locked in the tool holder.

5. To remove a bit pull back the tool holder locking sleeve

7

and pull the bit out of the bit holder

6

.

OPERATION

Instructions for Use

WARNING:

Always observe the safety instructions and

applicable regulations.

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from power

source before making any adjustments or removing/

installing attachments or accessories.

Be sure the

trigger switch is in the OFF position. An accidental start-up

can cause injury.

Proper Hand Position (Fig. D)

WARNING:

To reduce the risk of serious personal injury,

ALWAYS

use proper hand position as shown.

WARNING:

To reduce the risk of serious personal

injury,

ALWAYS

hold securely in anticipation of a

sudden reaction.

Proper hand position requires one hand on the main handle 5 ,

with the other hand on the side handle 2 .

Operation Modes (Fig. A)

WARNING:

Do not select the operating mode when the

tool is running.

Your tool is equipped with a mode selector switch 4 to

select the mode appropriate to desired operation.

symbol

Mode

Application

Rotary

hammering

Drilling into concrete and

masonry

hammering

only

Light chipping

Bit Adjustment

Chisel bit position

adjustment

To Select an Operating Mode

• Rotate the mode selector dial so that the arrow points to the

symbol corresponding with the desired mode.

nOTE:

The mode selector switch 4 must be in rotary drilling,

rotary hammering or hammering only mode at all times. There

are no operable positions in between. It may be necessary to

briefly run the motor after having changed from 'hammering

only' to 'rotary' modes in order to align the gears.

Indexing the Chisel Position (Fig. A)

The chisel can be indexed and locked into 24 different positions.

1. Rotate the mode selector switch

4

until it points towards

the

position.

2. Rotate the chisel in the desired position.

3. Set the mode selector switch

4

to the “Hammering

Only” position.

4. Twist the chisel until it locks in position.

Performing an Application (Fig. A)

WARNING:

TO REDUCE THE RISK OF PERSONAL

INJURY, ALWAYS

ensure workpiece is anchored or

clamped firmly. If drilling thin material, use a wood

“backup” block to prevent damage to the material.

WARNING:

Always wait until the motor has come to

a complete standstill before changing the direction

of rotation.

Switching On and Off (Fig. A)

To turn the tool on, depress the trigger switch 1 .

To stop the tool, release the trigger switch.