6

English

Soft Start Feature

The soft start feature allows the tool to accelerate slowly, thus

preventing the drill bit from walking off the intended hole

position when starting.

The soft start feature also reduces the immediate torque

reaction transmitted to the gearing and the operator if the

hammer is started with the drill bit in an existing hole.

Active Vibration Control (AVC) System

For best vibration control, hold the tool as described in

Proper

Hand Position

and apply just enough pressure so the damping

device on the main handle is approximately mid stroke.

The active vibration control neutralises rebound vibration from

the hammer mechanism. Lowering hand and arm vibration,

it allows more comfortable use for longer periods of time and

extends the life of the unit.

The hammer only needs enough pressure to engage the active

vibraton control. Applying too much pressure will not make

the tool drill or chip faster and active vibration control will

not engage.

D

e

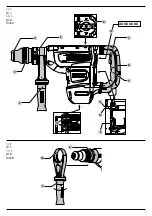

WALT Tool Tag Ready (Fig. A)(only for

D25733,D25773)

Optional Accessory

Your hammer comes with mounting holes 12 and fasteners

for installing a

D

e

WALT

Tool Tag. You will need a T20 bit tip to

install the tag. The

D

e

WALT

Tool Tag is designed for tracking and

locating professional power tools, equipment, and machines

using the

D

e

WALT

Tool Connect™ app. For proper installation of

the

D

e

WALT

Tool Tag refer to the

D

e

WALT

Tool Tag manual.

Lock-On Switch (Fig. A)(only for

D25733,D25773)

Chipping mode only

The lock-on switch 8 offers increased comfort in extended use

applications. To lock the tool on, depress the lock-on switch

while the tool is running. The tool will continue to run after the

switch is released. To unlock and turn off the tool, depress and

release the switch.

Electronic Speed and Impact Control (Fig. A)

The electronic speed and impact control allows the use of

smaller drill bits without the risk of bit breakage, hammerdrilling

into light and brittle materials without shattering and optimal

tool control for precise chiseling.

To set the electronic speed and impact control dial 9 , turn the

dial to the desired level. The higher the number, the greater

the speed and impact energy. Dial settings make the tool

extremely flexible and adaptable for many different appli cations.

The required setting depends on the bit size and hardness of

material being drilled.

• When chiselling or drilling in soft, brittle materials or when

minimum break-out is required, set the dial to a low setting;

• When breaking or drilling in harder materials, set the dial to

a high setting.

Overload Clutch

In case of jamming of a drill bit, the drive to the drill spindle is

interrupted. Because of the resulting forces, always hold the

tool with both hands and take a firm stance. After the overload,

release and depress the trigger to re-engage drive.

Mechanical Clutch

These tools are fitted with a mechanical clutch. The indication

that the clutch has activated will be an audible ratcheting

together with increased vibration.

Anti-Rotation System(only for D25733,D25773)

In addition to the clutch, an anti-rotation system offers increased

user comfort and safety through an on-board, anti-rotation

technology capable of detecting if the user loses control of the

hammer. When a jam is detected, the torque and speed are

reduced instantly. This feature prevents self rotation of the tool

reducing the occurrence of wrist injuries.

The anti-rotation system indicator

10

will illuminate to

indicate status.

Anti-Rotation and Service Indicator LED (Fig. A)

(only for D25733,D25773)

Your rotary hammer has two LEDs, indicating the Anti-rotation

(ADC) function and a service indicator. Refer to the table for

more information on LED functionality.

lED Function

Description

Red

(flashing)

lock-on/service

The anti-rotation system

indicator LED 10 lights up if

the lock-on switch 8 is used in

any mode except the chipping

mode or if there is a fault with

the tool or the brushes have

completely worn out

Red

(permanently on)

Anti-rotation

Anti-rotation is engaged, tool is

running at low speed.

Yellow

(permanently on)

Brush service

The yellow brushwear indicator

LED 11 lights up when the

carbon brushes are nearly worn

out, indicating that the tool

needs servicing within the next

8 hours of use.

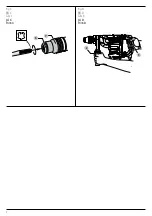

ASSEMBLY AND ADJUSTMENTS

WARNING: To reduce the risk of serious personal

injury, turn tool off and disconnect tool from power

source before making any adjustments or removing/

installing attachments or accessories.

Be sure the

trigger switch is in the OFF position. An accidental start-up

can cause injury.