MAINTENANCE

DAILY

1. Keep all movement points clean, dry and lightly lubricated.

2. Always keep bolts tight.

3. Check for oil leaks.

4. Keep air regulator set @ maximum 50-60 PSI.

5. Remove any accumulated moisture from air line filter.

6. Raise lift pads at day’s end and remove any standing water or moisture.

7. Use air blow gun to keep moving parts clean & dry.

MONTHLY

1. Wipe clean & lightly oil movement parts & lift pad stacking extensions.

2. Re-Torque the anchor bolts if necessary. (See CAUTION Below)

3. Check all connectors, bolts & pins to insure proper mounting & alignment.

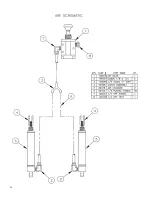

4. Make a visual inspection of hydraulic hoses & lines for possible wear or

interference.

5. Check fluid level of power unit (use Dexron III or equivalent).

CAUTION !

ALL ANCHOR BOLTS SHOULD ALWAYS BE TIGHT.

Check the bolts periodically and tighten if necessary to 60-90 ft. lbs.

If any of the bolts do not function for any reason, the lift should be

shut down until the bolt has been replaced.

10

Summary of Contents for BLAZER 9000

Page 4: ...4 Layout Dimensions...

Page 5: ...5 Layout Dimensions...

Page 6: ...6...

Page 14: ...13 921 8 17 5 48 30 17 PARTS MANUAL BLAZER 9000...

Page 15: ...14...

Page 17: ...16...

Page 19: ......