2

Safety Instructions

1. Always work on the vehicle with the lift on the safety locks.

2. Never allow unauthorized or non-trained personnel to operate lift. Thoroughly train new employees

in the use, care and safe operation of the lift.

3. Always lift the vehicle with four points of contact using either the lift frame, rubber pads or lifting arm

pads. Ensure that the four points of contact will not shift during operation.

4. Never use the lift to raise only one end or one side of the vehicle.

5. Always keep hands and feet clear of the lift when raising or lowering.

6. Keep area clean of tools, debris, grease and oil. Keep water from gathering on lift base.

7. Passengers should not be allowed inside the vehicle when in operation. Prohibit non-authorized

personnel from being in service area while in use.

8.

Capacity of the Blazer 9000 is 9000 lbs. Do not exceed the 9000 lb. capacity

.

Placing a Vehicle on the Blazer 9000

Note: It is critical that the operator positions the lift points per the vehicle manufacturers recommended

lift points. Some vehicle manufacturers have identified the proper lift points with triangular markings on

the undercarriage of the vehicle or have placed a label inside the front right door. If neither of these are

present, refer to the “

Lifting It Right

” Guides published by ALI or the “

Vehicle Lifting Points for

Frame Engaged Lifts

”, ALK/LP Guide.

1. The lift must be completely lowered before bringing the car over the lift. Install the rubber pads or

the lifting arms as required after the vehicle is centered over the lift and the vehicle lifting points

have been identified.

2. The lifting arms have extra height adapters that can be used depending on how high the vehicle

lifting point is from the top of the standard size lifting pad. The height adapters are 2-5/8” and 5”

and can be inserted into the adapter holes in the swing arms. Once the desired height is

determined, the standard lifting pad is set on the top height adapter.

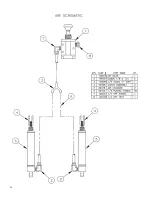

3. To raise lift, press the green raise button on the power unit. When you get to the desired height,

lower until it rests on the safety lock by pressing the red lower button on the power unit. When

you are ready to lower the lift, raise the lift off of the safety locks and press the air release

button releasing the safeties. While holding down on the air release button, press the red lower

button on the power unit. Swing arms out from under the vehicle and place them out of the way.

4. Be sure that the vehicle is stable on the lift and neither front nor rear heavy. With some vehicles,

the removal (or installation) of components may cause a critical shift in the balance and result in

vehicle instability. Refer to the vehicle manufacturer’s service manual for recommended

procedures when performing these services.

5. Be sure that arm pads and any adapters used are in secure contact with frame at vehicle

manufacturer’s recommended lift points.

7. Passengers should not be allowed inside the vehicle when in operation. Prohibit non-authorized

personnel from being in service area while in use.

Summary of Contents for BLAZER 9000

Page 4: ...4 Layout Dimensions...

Page 5: ...5 Layout Dimensions...

Page 6: ...6...

Page 14: ...13 921 8 17 5 48 30 17 PARTS MANUAL BLAZER 9000...

Page 15: ...14...

Page 17: ...16...

Page 19: ......