8

START UP, ADJUSTMENT

AND SAFETY CHECK

8.1

Starting the furnace

This appliance is equipped with a hot surface ignition device.

This device lights the main burners each time the room

thermostat calls for heat. See the lighting instructions on the

furnace.

During the initial start-up, it is not unusual for odour or smoke to

come out of any room registers. To ensure proper ventilation, it

is recommended to open windows and doors before the initial

firing.

The furnace has a negative pressure switch that is a safety

during a call for heat. The induced draft blower must pull a

negative pressure on the heat exchanger to close the negative

pressure switch. The induced draft blower must maintain the

negative pressure for the furnace to operate. If the induced

draft blower fails to close or maintain the closing of the pressure

switch, an error code would be displayed.

To properly start the furnace:

1. Set the thermostat to it lowest setting and turn off furnace

electrical power.

2. Remove the burner compartment control access door.

3. Make sure that the manual gas control is in the "ON"

position on the gas valve.

4. Replace the burner compartment control access door.

WARNING

Failure to replace the burner door can cause

products of combustion to be released into the

conditioned area resulting in personal injury or

death.

5. Turn on the manual gas stop.

6. Turn on the furnace electrical power.

7. Put thermostat to «Heat» mode and set it at least 10°F

above room temperature.

8. After the burners are lit, set the room thermostat to the

desired temperature.

These furnaces are equipped with a manual reset limit switch in

the burner assembly. This switch opens and shuts off the power

to the gas valve if an overheat condition (flame rollout) occurs.

Correct inadequate combustion-air supply or improper venting

conditions before resetting the switch.

DO NOT jumper this

switch.

Before operating the furnace, check the flame rollout

manual reset switch for continuity. If necessary, press the button

to reset the switch.

8.2

SELECTING THE BLOWER

SPEED

The selection of blower speed can be adjusted using

dipswitches.

Each selection (A,B,C,D) refers to a different

airflow. The ideal airflow in heating and in cooling mode can

be selected independently. Refer to table 11 and 12 for the tap

selection and CFM tables 15 to 20 for airflows.

You also have the ability to increase or decrease airflow by

approximately 15% with the «adjust» dipswitches.

These

setting will be applied to cooling and heating mode. Refer to

table 13.

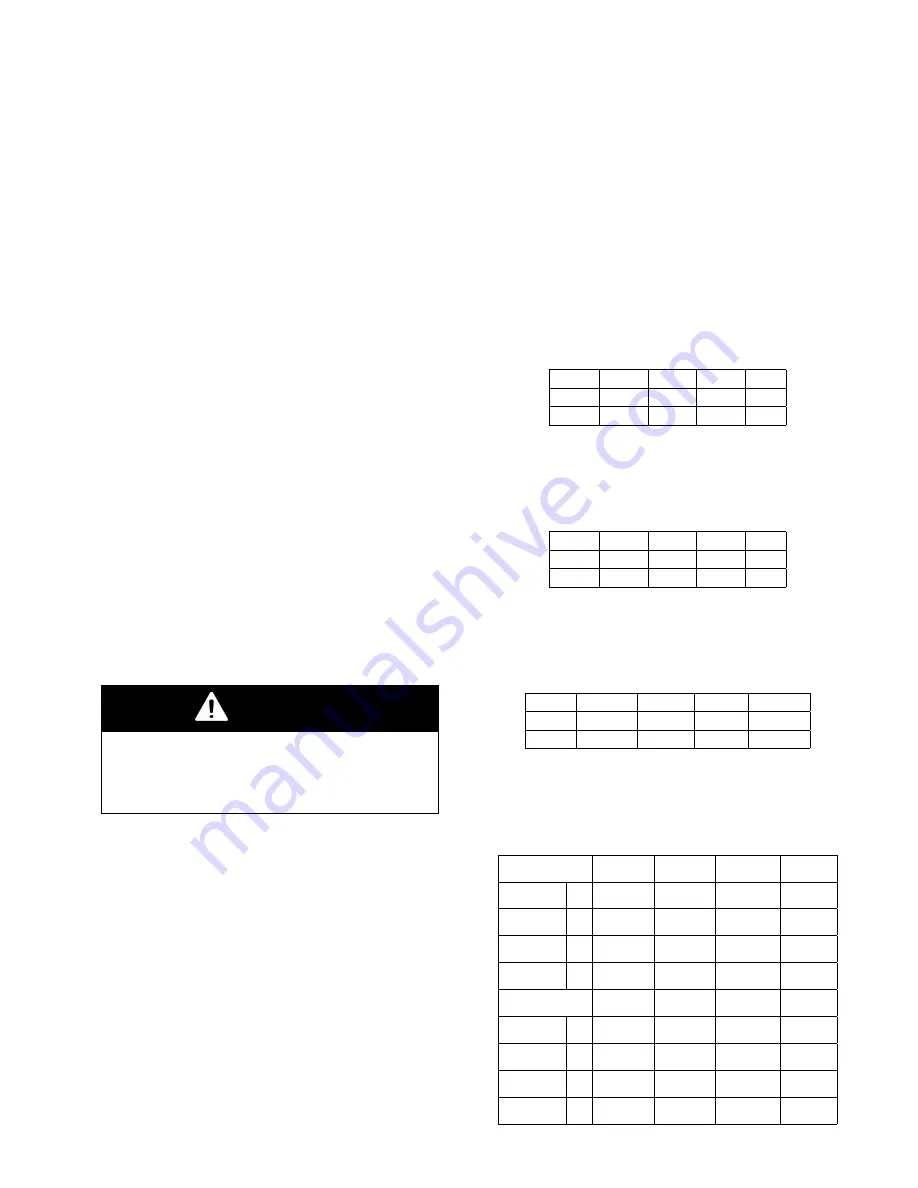

Table 11 – Cooling tap selection

A

B

C

D

S3-1

OFF

ON

OFF

ON

S3-2

OFF

OFF

ON

ON

Table 12 – Heating tap selection

A

B

C

D

S4-3

OFF

ON

OFF

ON

S4-4

OFF

OFF

ON

ON

Table 13 – Adjust tap selection

NONE

+15%

-15%

NONE

S3-3

OFF

ON

OFF

ON

S3-4

OFF

OFF

ON

ON

Table 14 – CFM C15-2-V - 0381123A

Dipswitch

Max ESP

1st stage

2nd stage

Temp.

Settings

"w.c.

heating

heating

rise °F

S4-3=OFF

A

1.0

235

295

45

S4-4=OFF

S4-3=ON

B

1.0

210

561

50

S4-4=OFF

S4-3=OFF

C

1.0

185

480

55

S4-4=ON

S4-3=ON

D

1.0

170

215

60

S4-4=ON

Dipswitch

Max ESP

1st stage

2nd stage

FAN ON

Settings

"w.c.

cooling

cooling

(G)

S3-1=OFF

A

1.0

800

1 000

440

S3-2=OFF

S3-1=ON

B

1.0

640

800

350

S3-2=OFF

S3-1=OFF

C

1.0

480

600

265

S3-2=ON

S3-1=ON

D

1.0

320

400

175

S3-2=ON

26

Summary of Contents for C105-2-V

Page 24: ...Figure 29 Direct vent clearance 23 ...

Page 25: ...Figure 30 Other than Direct vent clearance 24 ...

Page 32: ...Figure 31 Dimensions 31 ...

Page 33: ...Figure 32 Two Stage ECM Wiring diagram 32 ...

Page 36: ...Figure 33 Exploded view Cxx 2 V part 1 35 ...