8. Reroute the vent collector drain tube to one of the 1/2”

stubs of the drain trap. Cut the provided 1/2" tubing at

the appropriate length to reach the drain trap.

9. Connect the outlet from the drain trap to the condensate

drain piping using a ½” PVC tee. If a condensate pump

is used, make sure it is approved for acidic condensate.

10. Prime the drain trap with water.

This will ensure

proper furnace drainage at startup and will avoid any

recirculation of flue gas.

11. On the remaining 3 outlet stub, connect caps (1x5/8” and

2x1/2”). These caps are provided in the parts bag.

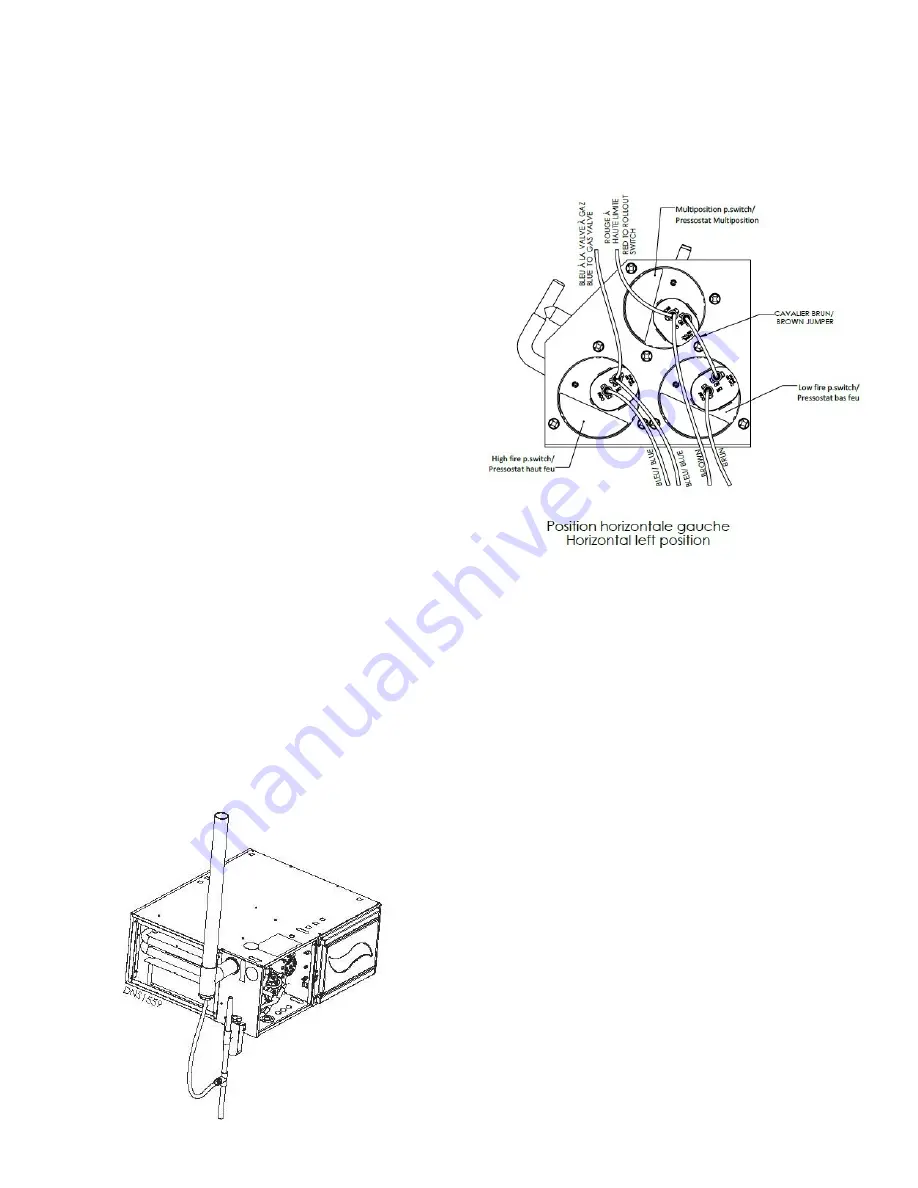

3.4.2

Alternate drain trap location in

horizontal left position

Figure 11 – Drain trap alternate position

3.4.3

Horizontal left multiposition

pressure switch connection

Figure 12 –

Horizontal left pressure switch

connection

The 3/16" stub just beside the drain of the condensate box must

be drilled or cut open. Use the supplied black squared PVC

tubing to connect the pressure switch (-0.2 in. w.c.) to this stub.

(see figure 10)

The pressure switch must also be electrically connected in

series with the low fire pressure switch (top) using the brown

jumper furnished in the parts bag. Refer to figure 12 for more

details.

3.5

MULTIPOSITION VENTING

DRAINAGE

All furnaces with horizontal exhaust vent piping must have drain

tee assembly and trap installed in the exhaust pipe as close to

the furnace as possible. See Figures 3, 6 and 10.

4

DUCT INSTALLATION

4.1

GENERAL REQUIREMENTS

The duct system should be designed and sized according

to accepted national standards such as those published

by: Air Conditioning Contractors Association (ACCA), Sheet

Metal and Air Conditioning Contractors National Association

(SMACNA) or American Society of Heating, Refrigerating

and Air Conditioning Engineers (ASHRAE). Consult The Air

Systems Design Guidelines reference tables available at your

local distributor.

The duct system should be sized to handle the required system

design aiflow at the design external static pressure.

The

13

Summary of Contents for C105-2-V

Page 24: ...Figure 29 Direct vent clearance 23 ...

Page 25: ...Figure 30 Other than Direct vent clearance 24 ...

Page 32: ...Figure 31 Dimensions 31 ...

Page 33: ...Figure 32 Two Stage ECM Wiring diagram 32 ...

Page 36: ...Figure 33 Exploded view Cxx 2 V part 1 35 ...