SECTION 3.4

DDFP

Page 27

Max.

PPM

Boron (B)

Nitrite (NO2)

Nitrates (NO3)

Silicon (Si)

Phosphorous (P)

pH

1000

800

1000

50

300

8.5

Min.

PPM

1500

2400

2000

250

500

10.5

To properly check inhibitor concentrations it may be neces-

sary to contact your local DDC Distributor/Dealer for assis-

tance. Refer to P arts Information Section 6, Page 45, to

obtain the DDC part number for the F

actory Coolant

Analysis Kit. This kit can be purchased for nominal fee for

analyzing the condition of the engine's coolant.

PROCEDURE FOR FILLING ENGINE

During filling of the cooling system, air pockets may form.

The system must be pur ged of air prior to being put in ser-

vice. This is best accomplished by f illing with a pre-mix

solution, to the top of f iller neck. Install the pressure cap,

start and run engine until the temperature staabilizes at

approximately 170° - 190° F (77° - 91° C). During this

warming process, you may

see coolant coming from the o verflow tube attached at the

pressure cap location. This is a normal condition since the

coolant expands as it heats up. When the o verflow ceases,

stop the engine.

NOTE:

Air entrapment in I-53 engines is v ery lik ely to

occur due to cooling system design. Upon initial

fill with a pre-mix solution. It is recommended that

the coolant be allowed to stand for a four hour peri-

od prior to starting.

To verify that the coolant is at a safe operating level, it's best

to wait until the engine temperature drops to approximately

120°F (49°C), or lower, before removing the pressure cap.

After the cap is removed, the level should be within 2 inch-

es (51mm) of the filler neck.

NOTE:

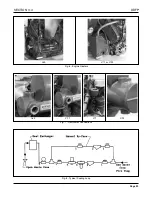

I-71 engines have incorporated the use of a coolant

recovery bottle (white plastic bottle) Fig

4

. During

initial filling of the cooling system, it will be nec-

essary to f ill the Reco very Bottle to the Cold Full

line with the pre-mix solution. Start and run the

engine as indicated abo ve. After reaching normal

operating temperature check the coolant le vel in

the recovery bottle to v erify that the le vel is at the

Hot Full line, if not add coolant to the bottle.

Following the same instructions as abo ve, wait for

the engine coolant temperature to drop before

removing the pressure cap.

The coolant le vel

should be at the pre viously mention height. The

coolant level must remain between Hot and Cold

run lines on the recovery bottle.

CAUTION:

Do not remove pressure cap while coolant is at

normal operating temperatures. Possible per-

sonal injury could result from the expulsion of

hot coolant.

PRESSURE CAP

Like most cooling systems, the Heat Exchanger type oper-

ates under pressure. A typical cap shown in Fig.

5

maintains

system pressure to raise the coolant boiling point and per-

mits a some what higher operating temperature without

coolant loss. Pressure cap values can vary in different engine

series. Refer to Section 5 for your engine type.

All pressure caps include a vacuum valve which opens dur-

ing cool down. This prevents an internal vacuum from being

formed which could contrib ute to leaking seals and hoses

collapsing.

NOTE:

I-71 engines use a coolant reco very bottle. The

pressure cap includes a rubber ring-type seat.

When the cap installed this ring forms a positi ve

seal between the filler neck and cap. During engine

cool down, if the wrong type cap is used, coolant

cannot transfer back into the heat e xchanger from

the recovery bottle. This can progress into an over-

heated engine and possible damage.

Fig. 5 - Typical Coolant Cap

Fig. 3 - Proper Concentrations Of Inhibitors

Fig. 4 - Coolant Recovery Bottle