DDFP

SECTION 3.3

LUBRICATION SYSTEM

OPERATION

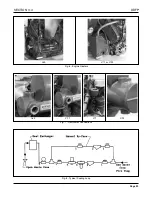

The lubricating oil system is schematically illustrated in

Figures 1, 2 and 3 for the Inline and VEE engines. The sys-

tem consists of an oil pump, oil cooler, a full-flow oil filter,

by-pass valves at the oil cooler and filter, and pressure regu-

lator valves at the pump and in the c ylinder block main oil

gallery. Positive lubrication is ensured at all times by this

system.

Oil for lubricating the connecting rod bearings, piston pins,

and for cooling the piston head,

is pro vided through the

drilled hole in the crankshaft from the adjacent forw

ard

main bearings. The gear train is lubricated by the o verflow

of the oil from the camshaft pock et through a connecting

passage into the flywheel housing from the camshaft, bal-

ance shaft, and idler gear bearings. The blower drive gear

bearing is lubricated through an e xternal pipe from the rear

horizontal oil passage of the cylinder block.

On the Inline engines the oil from the cam pocket enters the

blower and overflows through two holes, one at each end of

the blo wer housing, providing lubrication for the blo wer

drive gears at the rear end and for the go vernor mechanism

at the front. On the VEE engines, the blower drive gear is

lubricated from the rear of the blower.

OIL COOLER

All engines use a plate type oil cooler. Between each engine

model, the major difference lies in the number of plates in

each cooler. The number of plates required is determined by

engine horsepo wer de veloped. All the oil cooler systems

incorporate oil bypass valves in the event of plate core plug-

ging.

It should be understood that improper engine maintenance

could adversely effect the ef ficiency of the oil cooler sys-

tem. Please refer to the technical data Section 5, for specif-

ic lube oil temperature and engine coolant temperature

ranges for each engine model.

LUBE OIL FILL

On I-71 engines, the oil fill is located on the right rear . On

the VEE engines, it is found in the right bank v alve rocker

cover. On the 53 Series engine, the oil fill is also located on

the rocker cover. See technical data, Section 5 for oil v ol-

umes and specif ications on each engine model. A typical

oil fill location is shown in Figure 5

,

Page 24.

OIL LEVEL DIPSTICK

On most DDFP engines, the dipstick is located on the lower

left side. Exceptions are the I-71 and 12V92 models where

the dipstick is located on the right. Oil level can be checked

only when the engine is at rest (not running). Oil levels must

be maintained between the low and full marks.

NOTE:

Due to the basic engine design, DDC engines

retain large volumes of oil in the block while

running. For this reason, proper oil level cannot

be checked immediately after engine shut of f.

Wait approximately 10 minutes before check-

ing oil le vel. Do not add oil to a running

engine; overfilling can occur!

LUBE OIL PUMP

The positive displacement gear type pump is mounted to the

main bearing caps on I-71 and dri ven from the front end of

the crankshaft. On the I-53,V-71 and V-92 engines the pump

is found in the lower front cover and driven by the front end

of the crankshaft. The I-71, V-71 and V-92 have a pressure

relief located on the dischar ge side of the pump,

which

maintains pressure being delivered to the oil filter and cool-

er. The I-53 engine does not use a pressure relief v alve but

does incorporate the use of the f ilter and oil cooler bypass

valve to maintain pressure.

All four engines use an oil pressure regulator valve to main-

tain oil g alley minimum pressures. See technical data

Section 5 for specifics per engine model.

Page 20